Naked Engineering - Bioreactors to Grow Your Bacteria

Interview with

Meera - For this week's Naked Engineering, Dave and I are exploring the field of fluid mechanics, so the forces and movements of fluids such as liquids and gases. But Dave, this is still quite a big area so what are we focusing in on?

Dave - Yes. Fluid dynamics is a huge area, ranging from aircrafts to things which are much smaller scale and actually things that you come across in everyday life. One of the very difficult bits of fluid mechanics is when  you have more than one phase - so a solid and a liquid, or two different types of liquid, or also liquid and gases - all mixed together. Studying how these mix together and how they interact is very, very important at all sorts of scales, not least when you're cooking, or on a much larger industrial scale doing chemical reactions, or even biological reactions.

you have more than one phase - so a solid and a liquid, or two different types of liquid, or also liquid and gases - all mixed together. Studying how these mix together and how they interact is very, very important at all sorts of scales, not least when you're cooking, or on a much larger industrial scale doing chemical reactions, or even biological reactions.

Meera - To find out a bit more about this mixing process on an industrial scale biologically, we've come along to University College London this week to meet Martina Micheletti who's a lecturer in Biochemical Engineering. Now Martina, your particular area is bioreactors?

Martina - Yes. A bioreactor basically refers to reactors in which drugs are actually produced by lab organisms, for example microbial yeast or a mammalian cell culture. They need an aseptic environment and have a lot of sterilisation issues.

Dave - Essentially, it's a tank where you can grow lots and lots of cells which have been bred or engineered to produce a useful product. Quite often a drug.

Martina - Yes. So, the kind of geometry they will use, the most common one, is a sort of cylindrical tank with a rotating impeller in the middle. The mixing is achieved by stirring and there is an impeller, which can be of different designs, rotating at a certain speed.

Meera - So a bioreactor is essentially a vessel where you're trying to culture cells. What are you actually doing inside this, or what are the conditions inside it, to allow these cells to culture and be happy?

Martina - Definitely you need some sort of a food. So nutrients - usually in the form of powders in an aqueous medium. But cells, in order to live and grow, they need oxygen. We usually have a pre-filtered air inlet inside the bioreactor. Also, live organisms have got required temperatures and pH. Usually, temperature can be 37 degrees and pH can be pH 7. So temperature and pH have to be controlled as well.

Dave - I guess if you've got quite a big vat full of cells, a really major issue is to make sure all the cells are happy at the same time.

Martina - Definitely. So, what you need mixing for is, first of all, to actually maintain a suspension of cells so they don't sediment. You also need to mix the nutrients, so again they can be taken up by the cells.

Meera - So you've got gases and you've got nutrients in there, all of these need mixing, for which you've got a propeller. Do you essentially just keep this going very fast to get things mixed?

Martina - Well you know, you'd think so. However, there are a number of issues. A lot of these organisms are quite fragile. Mammalian cells for example don't have a cell wall. Some impellers produce quite high shear rates and that can be detrimental.

Dave - So the shear is just the rate of change of velocity. So if you've got one side of the cell going a lot faster than the other side of the cell it will get ripped apart.

Martina - Yes. When we take an individual cell inside a bioreactor, that's going to be subjected to different forces and force stresses.

Meera - So how do you set about monitoring the flow through the vessel, how things are mixing, and the forces in there?

Martina - What we really want to get is a flow pattern of the impellers as well as have a quantified turbulence level and also get an idea of the sort of energy which is dissipated by the impeller. There are a number of techniques to do these. I would say that the most advanced one is laser based. One of them is for example, particle image velocimetry.

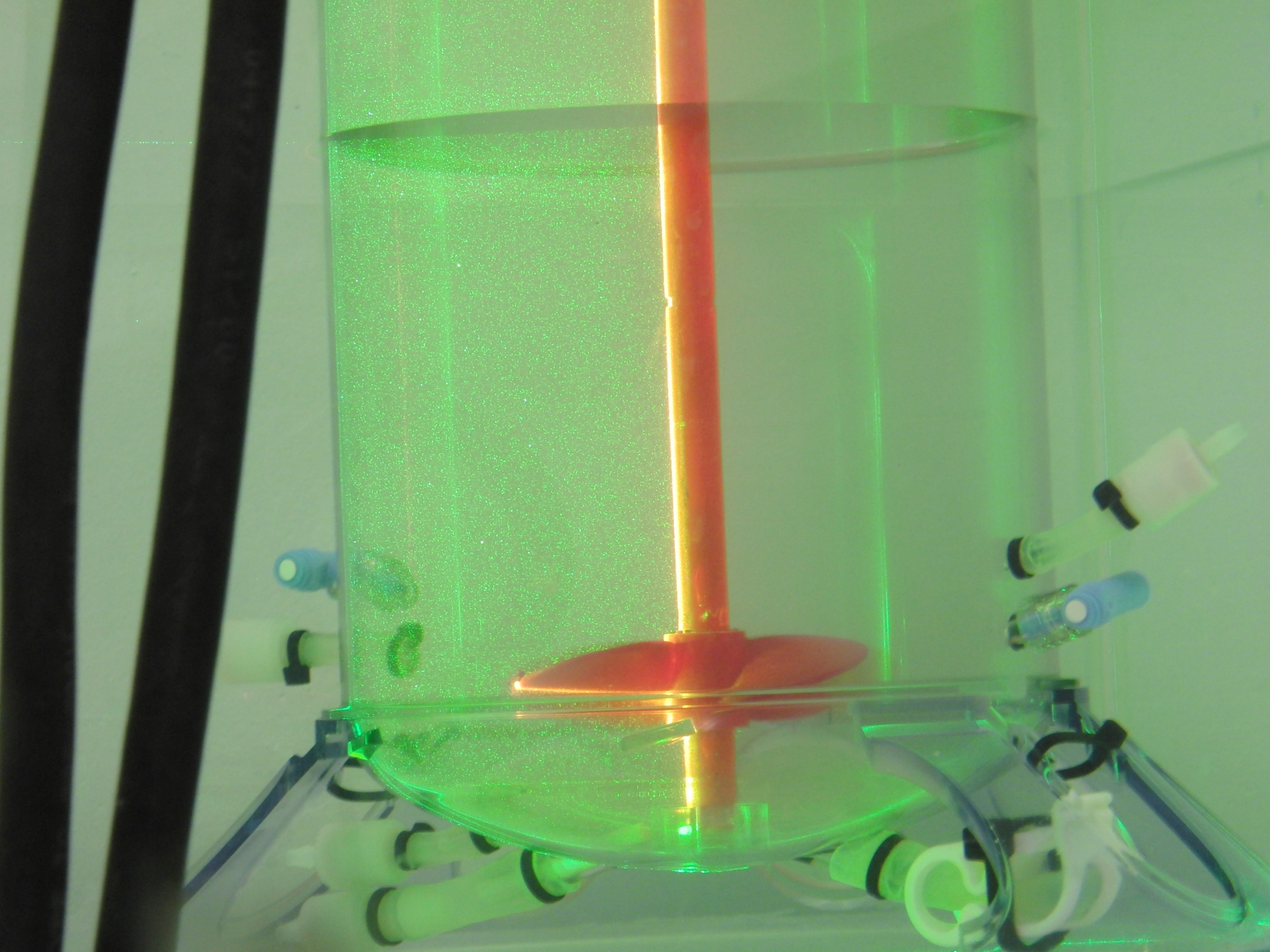

Meera - So we've got a laser here which is pointing at a scaled down bioreactor vessel. It's about 15 centimetres in diameter and it's got a propeller going through the middle of it. It also has a misty fluid in that vessel.

Martina - It's an image technique essentially that works with seeding particles that follow the fluid.

Martina - It's an image technique essentially that works with seeding particles that follow the fluid.

Dave - So the problem with seeing how the fluid is moving is that the fluid is transparent and you can't see it. So you've added seed particles which are very very small and will move with the fluid. So, if you know where they're moving, you'll know how the fluid itself is moving.

Martina - Exactly. So in fact, I can turn it on now and show you.

[Laser turned on]

Meera - So you set it going now and this clicking sound that we can hear is the laser firing quite frequently at the vessel in front of us.

Martina - This is basically a high power laser that is producing two pulses at a known time interval. I set it at 1 millisecond from each other and it is basically producing a light sheet inside the bioreactor.

Dave - So you're using a sheet rather than just illuminating the whole bioreactor. So you're only illuminating the particles in that sheet and you get a sort of 2-dimensional picture.

Meera - How does putting a sheet of light over this allow you to see the velocity of these seeded particles?

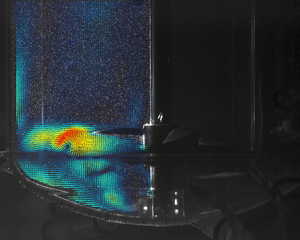

Martina - There is a high speed camera just in front of the bioreactor which is focused exactly on the actual plane where the laser is firing. The cameras can actually take two images and the camera is synchronised with the laser, so it's going to take the two images at the same time intervals as the laser pulses. The two images are then cross correlated to actually find out the average space travelled by a particle.

Meera - But now, on a computer screen here, we can see quite a close up image of the propeller and the seeded particles moving around it.

Martina - Based on the images that you see now, the computer is then able to actually get a lot of information about the velocity of each of the particles at that location and at that time.

Dave - A bit like how a speed camera works, it will flash twice and look at how your car has moved in between, so you have then got to use a computer to work out how far these particles have moved.

Martina - Yes, exactly.

Meera - How are you then using this information about the velocity of the particles?

Martina - I'll give you an example. We found recently in these type of bioreactors  that there were a number of instabilities. Basically, we found the existence of a vortex processing around the impeller shaft at a known frequency. By actually locating the feeding pipe, which is used in a bioreactor for example to feed glycerol to the cells when they need it etc, exactly inside the vortex it would decrease the mixing time (the time needed to achieve full mixing) by 50%. Which is quite a lot of energy saved.

that there were a number of instabilities. Basically, we found the existence of a vortex processing around the impeller shaft at a known frequency. By actually locating the feeding pipe, which is used in a bioreactor for example to feed glycerol to the cells when they need it etc, exactly inside the vortex it would decrease the mixing time (the time needed to achieve full mixing) by 50%. Which is quite a lot of energy saved.

Meera - And I guess also, when it comes to the manufacturer of say bioreactors, you've got a 15-centimetre scaled vessel here but then hopefully you'll be able to scale this up for the industrial level of pharmaceutical companies?

Martina - Scale up studies are something that are very sought of after by industry. This is a 2-litre vessel but we go even lower down to 2ml scaled vessels. All the fluid dynamics information that is small scale would allow a pharma company for example to actually come and scale up the production of a drug from a 2-litre scaled to a 200-litre possibly.

A video of this research can be seen at

thenakedscientists.com/engineering.

Comments

Add a comment