Resurrection Plant tropical vaccine key

Interview with

Chris - Scientists have announced that they've discovered a way to use a secret, known previously only to nature, to solve a big problem in the third world; how do you keep viruses, and particularly live viruses that you're going to use as vaccines, alive despite a lack of refrigeration? The secret has come from a plant called the Resurrection Plant, which is an incredible organism. It can withstand near total desiccation. You can dry it out for months on end, in some cases years, and then it springs back to life as soon as it touches water. Scientists have discovered how the plant does that and they've now been able to borrow the same trick and apply it to viruses. Matt Cottingham joins us from the University of Oxford, lets start with the plant first. How does it do this?

Matt - Well the key is that it has lots of trehalose inside its cells. Trehalose is a common sugar, similar to sucrose which is ordinary table sugar. When the sugar dries out, it forms a glass; a glass is a particular type of chemical entity which is essentially a liquid but so viscous that it's effectively a solid. Actually, the glass in your window is called glass because it's that type of chemical, and although it seems completely solid, it's actually chemically a liquid because the molecules are disordered.

Chris - So it presumably stabilizes the cells and the components of those cells in the plant, so that when the plant dries out, the chemicals and their structures don't fall apart. So when you do add water, the sugar then breaks down again, and everything  comes back to life?

comes back to life?

Matt - That's right. If you take all the water out of something, what would normally happen is you get crystals, and crystals have a very tight structure and they will actually disrupt the structure of the plant, or in this case the vaccine, which you want to preserve. So by having lots of sugar which doesn't crystallize under those conditions, but instead forms a glass, that actually allows protection against desiccation.

Chris - So how have you stolen what the plant is doing and applyed this to the vaccine technology world?

Matt - Well, it's very simple. We simply take a mixture of sucrose and trehalose, and formulate the vaccine into that and then dry it. And what we've hit upon is a particular method of drying that actually enables the vaccine to retain its structure and its activity.

Chris - Which viruses are you thinking of because obviously, there are certain viruses that are pretty stable and you don't need to do special tricks to make sure that people can get infected with them. I'm thinking of common things like norovirus which people catch on cruise liners. Not all viruses are as stable as that though.

Matt - That's right. So most viruses are quite stable but they really need to remain wet, so they're normally transmitted in droplets, say from a sneeze or via the faecal/oral route where you've probably got a tiny bit of moisture on your fingers. But in this case, if we want to be able to stabilize this, it's really crucial to have them dry because if they're dry, then the chemistry which should normally degrade them can't actually happen.

Chris - So which viruses are you looking to use and how?

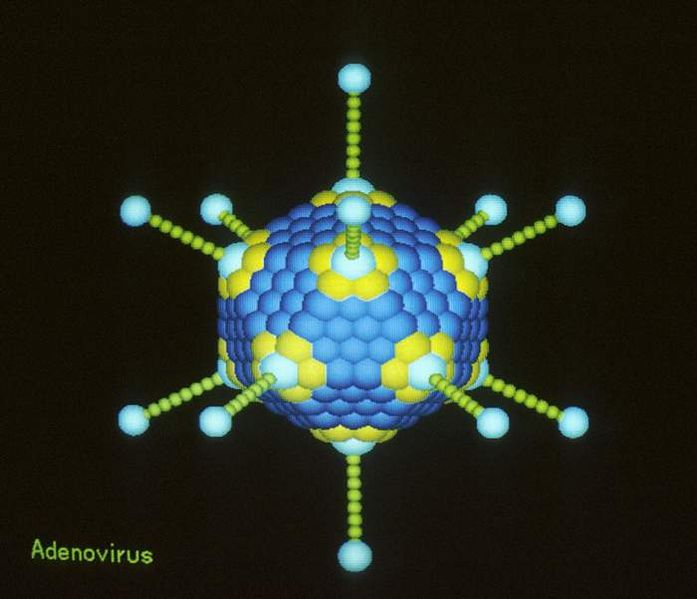

Matt - So, we focused in this work on two viruses, adenovirus and a pox virus called 'modified vaccinia virus'. These are exciting because they're two viruses which may be used to form the platform for a new generation of vaccines against diseases like malaria and HIV, and TB where there aren't any vaccines or where the current vaccines are no good.

Matt - So, we focused in this work on two viruses, adenovirus and a pox virus called 'modified vaccinia virus'. These are exciting because they're two viruses which may be used to form the platform for a new generation of vaccines against diseases like malaria and HIV, and TB where there aren't any vaccines or where the current vaccines are no good.

Chris - And what is the impediment or problem with using these agents in the third world at the moment?

Matt - Well, the problem is that they're live viruses. So, they're living organisms and they're very sensitive to heat, so all the live viral vaccines at the moment have to be kept in the fridge. They're usually manufactured in Europe and they're shipped all over the world in refrigerated containers, and they even have to be kept in the fridge at their destination. If they do warm up, then they essentially have to be thrown away.

Chris - I would presume then that the actual spend on keeping vaccines cold probably makes up a significant proportion of the total cost of the vaccine then?

Matt - Yes. It's about 20 percent and that doesn't include wastage.

Chris - Which is a huge amount and obviously, totally beyond the realms of many countries to spend money or even to have the infrastructure to keep a vaccine cold. So presumably your platform would enable you put viruses into these sugar glasses. They would therefore be stable at what sorts of temperatures, for how long?

Matt - We've managed 45 degrees for six months.

Chris - Which is pretty impressive.

Matt - Yes. It's amazing.

Chris - You presumably then would just take the vaccines out to the bush in the middle of nowhere and they would remain stable until someone had them administered?

Matt - That's right, yes.

Chris - Do you think that these sugars would be safe in the body?

Matt - Yes. They're completely safe.

Chris - How do we know that?

Matt - They are actually already used in the current vaccines . Some of the current vaccines. So it's a combination of these sugars together with the new method of actually performing the drying that has enabled us to do what we've done.

Chris - Any idea when you'll be able to wheel this out and when people will begin to see the benefit of this?

Matt - Yes. We're thinking possibly as early as 5 years, maybe more like 10 because we've done this very much on a laboratory scale. So now, we have to actually do it according to good clinical manufacturing practice which is a set of legislations which we need to adhere to in order to make a product that could actually be used in humans. That's being done by our commercial partners, Nova Laboratories in Leicester.

Chris - All right. Well, we wish you luck with it and thank you very much for joining us, Matt, and telling us about your work. That was Matt Cottingham. He's at the University of Oxford and he and his colleagues have published a paper - it's in Science Translational Medicine this week - in which they outline how these new sugar-based glasses can be used to make viruses survive intact in very otherwise hostile conditions.

Comments

Add a comment