In this week's Naked Scientists NewsFlash we find out why general health checks are generally unhelpful, how nanotech can make steam from sunlight and the discovery of "white noise" for your nose. Plus, how a new technique can print replacement cartilage in 3D...

In this episode

00:22 - General Health Checks Generally Unhelpful

General Health Checks Generally Unhelpful

A systematic review of research into general health checks shows that, although they increase the number of diagnoses, they do not reduce the number of deaths from cardiovascular disease or cancer.

Routine health checks, or testing healthy people for indicators of a range of conditions, are common elements of healthcare in some countries. The idea is that, by checking regularly for risk factors such as high blood pressure or high cholesterol, we should be able to reduce morbidity and prolong lives. It seems a very worthwhile aim, and intuitively we feel that health checks should be a good thing.

Routine health checks, or testing healthy people for indicators of a range of conditions, are common elements of healthcare in some countries. The idea is that, by checking regularly for risk factors such as high blood pressure or high cholesterol, we should be able to reduce morbidity and prolong lives. It seems a very worthwhile aim, and intuitively we feel that health checks should be a good thing.

However,

as we discussed with regards breast cancer screening a few weeks ago, there is always a risk of over-diagnosis - finding evidence of a condition that would not have become a problem, and potentially therefore recommending unnecessary treatments.

Little research has been done to see if health checks actually achieved their aims. So now, a team at the Nordic Cochrane Centre in Copenhagen led by Dr Lasse Krogsbøll combined data from 14 studies into a meta-analysis to examine the pros and cons of health checks.

Publishing in the British Medical Journal, Krogsbøll and colleagues looked at mortality, morbidity, number of diagnoses, hospital admissions, referrals to specialists and a number of other factors indicating health, including self-reported health, worry and absence from work. They used this to compare screened populations with those that received no intervention, in studies with between four and twenty two years follow up.

Although the results varied between studies, this meta analysis found no evidence in the health-checked group for a reduction of either total mortality, or deaths through cardiovascular disease or cancer. There was evidence for an increase in diagnosis, but as this didn't lead to a change in mortality, we can assume that these are often over-diagnoses.

So what does this say for general health checks? The authors argue that these health checks may appeal to people who need them less, and point out that doctors already carry out screening in patients where they think it's needed, and conclude that health checks "do not work as intended". In a related Editorial piece, Domhnall MacAuley suggests that "Policy should be based on evidence of wellbeing, rather than on well meant good intentions."

04:20 - Turning fish farm waste into cash

Turning fish farm waste into cash

Intensive salmon farms have revolutionised the supply of salmon making it accessible to far more people than before, but they do have serious problems. Many of these are caused by the prodigious amount of food that the salmon are eating. This contains a large amount of nutrients, both in the form of energy, and in the form of nitrogen and phosphorous which act as fertilisers. Some of these end up making up the salmon, but most are either missed by the salmon, or pass straight through, and can cause algal blooms and seriously alter the balance of the ecosystem.

Kjell Reitan from the Norwegian University of Science and Technology is working on the old adage that "where there is muck there is brass", essentially considering these inputs as a resource rather than a problem.

Kjell Reitan from the Norwegian University of Science and Technology is working on the old adage that "where there is muck there is brass", essentially considering these inputs as a resource rather than a problem.

Only about 30% of the fish food is used by the salmon, the rest is released into the water. So the trick is to find something which will eat this food and turn it into something useful. Filter feeders are the natural answer so surrounding fish farms with mussel beds could transform the excess food into mussels which can of course be sold. He has found that waste fish food increases the rate of growth of the mussels and could produce 15,000-20,000 tonnes of extra mussels in Norway per year.

This still leaves the nitrogen and phosphorous fertilisers, which should be able to be used to fertilize plant growth. This can be a problem if the plants are small algae which choke off everything else, but if they are large seaweeds, such as Kelp, they can clean up the water and produce a resource which can be collected as a biofuel. In Norway alone there is the potential to grow 0.6 to 1.7 million tonnes of kelp from fish farm waste.

Together these could both clean up the environment and produce a resource worth 600 million pounds a year, which is a good example of looking at problems as opportunities.

07:49 - White Light, White Noise, White Smell?

White Light, White Noise, White Smell?

Just as you can see white light, and hear white noise, it seems we are also susceptible to a white smell - or "olfactory white".

"White" isn't a distinct frequency of light, rather it's the way we perceive light that is made up of a number of different wavelengths. Two different mixtures, even if they don't contain any of the same wavelengths, will still appear "white" to us if they contain enough different frequencies. Similarly, white noise contains a very wide range of different wavelengths of sound. The concept of "whiteness" seems to extend from having an equal intensity across a broad stimulus space. Now, according to research published in the journal PNAS, it seems the same is true for smells.

Talio Weiss, from the Weizmann Institute of Science, Israel and colleagues, selected 86 molecules that should span the full olfactory range, and diluted them so that they each had the same intensity. They then made a range of different mixtures - some spanning the full range, others more clustered - and asked volunteers to describe the smell.

They discovered that the more components two mixtures have, the more similar they smell, even if the two mixtures actually have no shared components. When the mixtures contained 30 components or more, they all smell alike - the olfactory equivalent of white noise.

They discovered that the more components two mixtures have, the more similar they smell, even if the two mixtures actually have no shared components. When the mixtures contained 30 components or more, they all smell alike - the olfactory equivalent of white noise.

The authors suggest that this is related to the way that human olfaction works - it's thought of as a synthetic, rather than an analytical sense. In other words, it considers the combination of stimuli, rather than each one individually. This can be seen in the pattern of brain activity - the activity for a mixed smell is not simply the combination of activity for all its components.

Furthermore, we're unlikely to encounter olfactory white in the wild. The smell of a rose, for example, is made up of many different components, but one, phenylethyl alcohol, is far more intense than the others. Coffee or wine are other good examples, with a range of components, but lacking uniformity and over a limited olfactory range.

The concepts of white noise and white light have been of huge benefit to understanding the neurobiology of hearing and vision. The authors argue that white smell may now help do the same for olfaction.

12:20 - Turning Sunlight into Steam

Turning Sunlight into Steam

Steam is useful for a huge number of purposes ranging from running steam engines to sterilising medical instruments, but producing it uses a huge amount of energy. This is particularly a problem if you only want a small amount of steam, as most of the energy you use goes into heating the water before it becomes steam.

Naomi Halas and collegues at the Rice Quantum Institute, Rice University have been improving the efficiency of this process, using a principle first used by Stevenson in his Rocket steam engine. Stevenson did it by sending the gasses from his fire through small pipes, dramatically increasing the surface area of the heater. Publishing in the journal ACS Nano, Halas et al have done it by spreading metallic nano-particles, each about a 20,000th of a mm across, throughout the water. This creates an enormous surface area and can absorb light very effectively. If you then focus sunlight onto the water the energy is absorbed by the particles and transferred to the water very quickly.

Naomi Halas and collegues at the Rice Quantum Institute, Rice University have been improving the efficiency of this process, using a principle first used by Stevenson in his Rocket steam engine. Stevenson did it by sending the gasses from his fire through small pipes, dramatically increasing the surface area of the heater. Publishing in the journal ACS Nano, Halas et al have done it by spreading metallic nano-particles, each about a 20,000th of a mm across, throughout the water. This creates an enormous surface area and can absorb light very effectively. If you then focus sunlight onto the water the energy is absorbed by the particles and transferred to the water very quickly.

Even without optimisation, about 24% of the energy goes directly into producing steam. This means that they can even produce steam directly from ice water.

The first place this could be used is for sterilising instruments in the third world, but it could be generalised to wherever there is plenty of sunlight and a requirement for steam.

15:15 - Printing New Cartilage

Printing New Cartilage

Dr. Anthony Atala, Wake Forest Institute for Regenerative Medicine

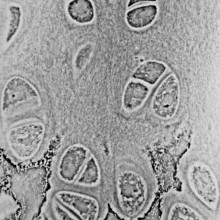

Ben - Researchers at the Wake Forest Institute of Regenerative Medicine have devised a new way to print out replacement cartilage in 3 dimensions and they've demonstrated that it works in a real animal. To find out more, we are joined by Dr. Anthony Atala, the director of the Wake Forest Institute. Anthony, thank you ever so much for joining us.

Anthony - Good to be with you.

Ben - So, why do we need to be thinking about printing artificial cartilage?

Anthony - Well, we've actually been working on creating cartilage for quite a number of years. There's a major need for cartilage of course for patients who suffer from conditions such as knee problems or problems with their joints. So, having an available source of cartilage would be a good thing for patients in the future.

Ben - What do we do at the moment when we need to make artificial cartilage or when we need cartilage for a patient? What are our options?

Ben - What do we do at the moment when we need to make artificial cartilage or when we need cartilage for a patient? What are our options?

Anthony - Well, there are not many options right now in terms actually putting cartilage in place. Once a cartilage wears out, it's very hard to actually put anything in there that would do a good job. So, surgery is done, but really, there's nothing better than real cartilage. Of course for example, if you have an accident where you have a hip fracture, you're putting in metal pieces in place instead of putting real ,what we call, elastic cartilage in place.

Ben - So what's been the basis of your work? What have you been doing?

Anthony - We basically have been focusing on creating tissues and organs using the patient's own cells. The concept is actually quite simple. We take a very small piece of tissue from the patient less than half the size of a postage stamp and we then are able to expand those cells outside the body, and we then can start creating new cartilage tissue that could be implanted into patients in the future.

Ben - And this tissue that you're growing outside of the body, does it have all of the right properties?

Anthony - Well, that is one of the things that we're working on, to make sure that they have the right properties. That is where the bioprinting comes in because you can actually lay down cells exactly where they need to be in a predisposed manner where you can actually programme a printer to do so.

Ben - Now, we've been hearing a lot about 3D printing recently. It does seem to be the future, but 3D printing of living tissue seems quite remarkable. Does it work in the same way, whereby you have a sort of inkjet head full of a cell culture and you just literally lay down the cells where you want them?

Anthony - That's exactly right. If you can picture your typical desktop inkjet printer, it really is utilising very similar technology. But instead of using ink, we're using cells. You have a printer that goes back and forth, and what we do is we modified printers so that they would print one layer at a time. So, instead of having a sheet of paper coming through one at a time, imagine printing on the same sheet of paper over and over again and just building up over the same area, until you make the 3-dimensional tissue that you need.

Ben - Do you need a scaffold on which these cells can grow or can you literally just print them into 3 dimensions and they'll hold their shape?

Anthony - No, you do need a scaffold actually. It's a good question and we use different materials as scaffolds. We use gels that look like gelatine if you will, then they will hold the cells together in their shape, and these gels can then harden to different consistencies as needed, and then we can also use fibres to print. And in fact, we have been able to use a combination of both gels and fibres for our printing technology.

Ben - So, when you've done this, how well did the cells survive and how well did they actually work when you did the mechanical tests that imitate what a real bit of cartilage is likely to go through?

Anthony - The cells survived nicely. In fact, what we do is we actually are using the same technology that you are familiar with in an inkjet printer. What happens is you have little air bubbles that gets formed inside the cartridge. You have little air bubbles that get formed and the cells get incorporated within those bubbles, and then basically then released without heat affecting the cells. So the cells come down through the inkjet printer through the print head without being damaged and then we're able to lay them down one layer at a time until they're able to form where they need to in terms of creating tissue with properties which are very similar to those in patients.

Ben - And do we think that in the future, this is a likelihood that we'll be able to just scan a knee for example and say, "Well, we need this exact 3D structure of cartilage. Let's print one out" and then surgically pop it in?

Anthony - Yes, that's in fact the direction that we're headed. We are actually building printers that have scanners in them. So what you do is, if you have the injured area, you actually scan the area and with the same piece of machinery, we are able then to go back and lay down the cells where they're needed in their correct 3-dimensional structure.

Ben - Fantastic! Well, that does at least sound like surgery of the future. Thank you very much, Anthony. That's Dr. Anthony Atala from the Wake Forest Institute of Regenerative Medicine.

Comments

Add a comment