Thermo-Electric Generators

Interview with

Chris - Incredible as it sounds, over 70% of the energy released when you burn the fuel in your car gets wasted. Most of it flows out of the exhaust pipe in the form of heat that we then throw away. With average oil prices higher than they've ever been, researchers are looking for ways to scavenge back some of that wasted energy to make some efficiency savings. The approach they're taking is to use Thermo-Electric Generators or TEGs that could turn heat into electricity and this is something that the UK's National Physical Laboratory, NPL, at Teddington is pioneering. One of their scientists, Laurie Winkless works on this technology. Hello, Laurie. Welcome to the show.

Laurie - Hi, Chris. Thank you.

Chris - So how do these devices work?

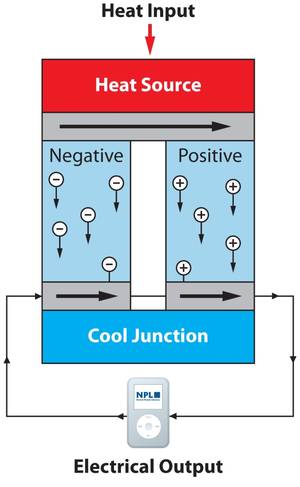

Laurie - Basically, a Thermo-Electric Generator is based on a semi-conductor material. It's sandwiched in between two pieces of ceramic with some electrical conductive material, maybe copper, in between. They effectively work by having a temperature gradient applied to the device and the bigger the temperature gradient, the more of a push that the charges in these materials get. So inside the semi-conductor, you have a positive charge and negative charge. So you have an electron which is a negative charge, and you also have something called holes which act as a positive charge. When you apply temperature gradients to one of these devices, you give energy to the charge carriers, so both the electrons and holes inside the material, it causes an electrical flow in the device. And when you add up several of these couples together, you get a very nice, very reliable force of electricity.

Chris - This physics sounds very cutting edge, but it isn't new, is it?

Chris - This physics sounds very cutting edge, but it isn't new, is it?

Laurie - Not at all. Actually, the first Thermo-Electric effects were discovered and described beautifully in the 1800s. So we've known about the theory for a long time. They've been used in the space industry probably since the '50s or '60s, but now down on Earth, we're starting to look into using them in a much more realistic way in the last, probably 10 to 15 years.

Chris - So what's the difference between what the physicists of yester year, in the 1800s would've done and what we're trying to do today?

Laurie - Well back in the 1800s, there was no information on semi-conducting materials for example. Everything was either an insulator or a conductor. Semi-conductors are relatively recent phenomenon. We take them for granted. They're in every piece of electronics in our house, but the discovery of semi-conductors and the application of those equations from the 1800s have led to a new way of producing electricity from a temperature gradient from heat.

Chris - So those early scientists were pretty clever and they worked out there would be an effect. They worked out this was theoretically possible and would produce very tiny voltages for them, but with the application of modern materials and modern engineering, we're in a position to produce actually meaningful voltages that could do something.

Laurie - Yes, indeed. They described the effect for a metal for example. So you get a very, very tiny voltage. In semi-conductors you get exactly that, a much more useful voltage that we can do something with.

Chris - So how are we actually trying to do that then?

Laurie - Well, at the National Physical Laboratory, our focus is on trying to understand the measurement around these materials. I always say to people, describing how these devices work is like trying to measure mass without knowing what the kilogram is. So we need to have that kind of measurement standard in place. There are actually a huge number of applications of these devices, the space industry being probably the one that's most established where they're used as a power source for deep space missions and beyond. The power plant industries are starting to catch up and the car industry are the ones who are most recently investing quite a lot of money in looking into using these materials and devices.

Chris - If I really am throwing away 70% of the energy in my fuel tank, that's a lot of money. It stands to reason then that if I take all of the hot parts of the engine and especially the exhaust, I ought to be able to get that energy back using one of these devices and turn it into an electrical flow that I could do something useful with. How much of a saving do you think I could make were I to implement this on my car today?

Laurie - So, there are quite advanced prototypes, by Ford and BMW for example, which have quite high wattages, but I haven't seen enough evidence to quote them to you. 5 years ago, they put one of these TEGs in, actually based an entire TEG system around the exhaust, so capturing all of the heat that's in the exhaust, up to 500 degrees in this particular car. They ran the car along the motorway, and they produced about 500 watts of power which equates to about 5% saving in fuel.

Chris - Which could save quite a lot of money, couldn't it, in the long run?

Laurie - In the long run, it's worth looking into at least. The devices themselves aren't amazingly efficient yet. We have a lot more work to do to make them incredibly efficient. But already, you can see a saving and you can see the improvement and the efficiency of the system of the car.

Chris - These things would flank the exhaust pipe or whatever heat source there was. So that's the hot side. You're giving the particles, these electrons and the holes, energy on the hot side. How do you then get them to move towards that cold side? How do you make the cold side to create the current flow?

Chris - These things would flank the exhaust pipe or whatever heat source there was. So that's the hot side. You're giving the particles, these electrons and the holes, energy on the hot side. How do you then get them to move towards that cold side? How do you make the cold side to create the current flow?

Laurie - The dream would be that you just use the airflow of car moving down the motorway for example. But the reality is that it's not a very reliable cold source. So what the car industry particularly is trying to use is the cooling system that already exists in the car. So it's generally something like ethylene glycol and they just reroute the cooling system to wrap around the TEGs and that produces the cold side.

Chris - And what sorts of materials, because you said semi-conductors quite generically but what sort of semi-conductors? What are the materials that we're using that had bearing fruit in this regard?

Laurie - At what would consider as lower temperature levels, so around 200 degrees Celsius, you have the quite exotic sanding, bismuth telluride. This is a semi-conductor device which, at that temperature, has a thermo-electric efficiency of maybe 5% or 7% - not a huge efficiency. But as the temperature variation increases, so as you have much hotter side versus a cold side, when you have maybe up to 500 degrees plus, you have to start looking at different materials because bismuth telluride is not great with those temperatures. You start to look at things like silicon, germanium based. So, materials we're actually quite familiar with already as they use in the electronics industry.

Chris - And critically, what about the cost of those materials? Are they readily available and fairly cheap or are we looking at a major price hike to save 5 pence on each refuel?

Laurie - Well bismuth telluride ones are actually extremely cheap, surprisingly cheap! You can get bismuth telluride TEGs which will produce about 100 watts for about 90 pounds. So about a pound of watt is generally quoted the higher...

Chris - Cheaper than a catalytic converter, isn't it, which is ridiculously expensive.

Laurie - Yeah, indeed. But when you get to the higher temperatures, the materials get a little bit more exotic, so the price will increase accordingly.

Chris - Now help me out with one frustration; if you have something that conducts electricity very well, it conducts heat very well. The electrons are jiggling around, and they then move through the material, making other things jiggle around, that's how heat transfers. So how do you get this efficiency where you have something which will let the electricity flow, the electrons, but keep the heat back? It sounds like a paradox.

Laurie - Yeah, it is indeed a paradox and it's actually a measurement issue too. If we want to know exactly how much electricity can flow through these materials, we need to know its electrical conductivity and we need to know it very accurately. We also need to know its thermo-conductivity - how happy it is to allow heat to flow through. So to measure one and not the other is actually extremely difficult. They're coupled together quite strongly. But one of the efforts on a research level, is to look at nanostructuring the material. Changing the shape of the material on the nanoscale to increase the number of barriers or interfaces that the heat and the electrons have to flow through. Electrons are pretty happy to bump their way through interfaces. Heat takes a bit more of a beating, so it slows down the heat flow through the material.

Chris - So you can't make a material which will allow electrons through but will frustrate the progression of heat through the material and therefore you can maintain a hot side and a cold side, and drive that current.

Laurie - You can to a degree, of course we are subject to laws of thermodynamics like everything else unfortunately. The idea is that you keep the temperature gradient for as long as you possibly can. You will always get hot and cold giving you warm at some point and you start to lose the power output at that point. But you can then cool the whole TEG down and restart the flow.

Chris - Love the pun on "to a degree" too, Laurie. Laurie Winkless from the National Physical Laboratory.

Comments

Add a comment