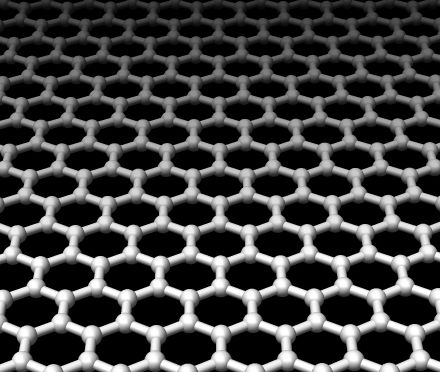

Scientists have made the world's thinnest ever transistors - the devices that switch current on and off in all electronic equipment. At their very smallest, the new transistors are just one atom thick and ten atoms wide. They're made of a material called graphene: carbon atoms joined together in a flat sheet.

The tiny transistors may herald a new breed of computer chips smaller and faster than our current ones based on silicon. The number of silicon transistors crammed onto a chip has so far doubled roughly every two years, as Intel co-founder Gordon Moore predicted in his 'law'. But there are limits to the capacity of silicon-based electronics, because current leaks out when components get very small - and the silicon material isn't stable enough to hold together when it's cut down to 10 nanometres.

The tiny transistors may herald a new breed of computer chips smaller and faster than our current ones based on silicon. The number of silicon transistors crammed onto a chip has so far doubled roughly every two years, as Intel co-founder Gordon Moore predicted in his 'law'. But there are limits to the capacity of silicon-based electronics, because current leaks out when components get very small - and the silicon material isn't stable enough to hold together when it's cut down to 10 nanometres.

Andre Geim at Manchester University thinks his nanometre-sized transistors could go beyond these limits. Unlike silicon, his team have found, graphene is stable and conducts electricity when cut into strips of only a few nanometres wide. Strong carbon-carbon bonds hold the honeycomb structure together even at room temperature.

Graphene conducts electricity so well that earlier transistors made of the stuff were too 'leaky': it was very difficult to turn the current off. But the Manchester team have controlled current flow by cutting ribbons of graphene of varying width, which changes the electronic properties of the material. The latest transistors are their smallest yet.

The transistors were etched out of bigger pieces of material - but this isn't a scalable approach quite yet: the team had to pick the right size pieces after using an imprecise etching tool.

"It is too early to promise graphene supercomputers," says Geim. "Unfortunately, no existing technology allows the cutting materials with true nanometre precision. But this is exactly the same challenge that all post-silicon electronics has to face. At least we now have a material that can meet such a challenge."

Comments

Add a comment