Train Tracks - how trains go round corners

Ingredients

| Some plastic glasses and a tube | A slightly sloping board | ||

| Some rails - hosepipe, or pipe insulation work well |

Instructions

First arrange your board so it is gently sloping, for a 60cm board lift one end 4-5cm

Now arrange your tracks about 1 1/2 cups apart - keep them the same distance apart and give them a slight curve. You may need to tape them down.

Now build your train wheels - the easiest way to do this is to tape two cups together.

Tape one pair with the wide ends together and another with the narrow ends together.

|  |

|---|---|

| Narrow ends together | Wide ends together |

Try rolling the tube and the cups down the slope. Which design stays on the best?

Result

You should find that the tube doesn't really stay on the track, the cups with the narrow ends together falls off even more quickly, but the cups with the wide ends connected together correct themselves and stay on the track.

Explanation

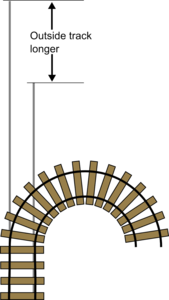

These are a good model for an axle of a railway train, the wheels are solidly attached to the axles, this has the problem that when you go around a corner the outer rail is longer than the inner one, so you really need one wheel to either run faster than the other (which is how cars manage) or make one wheel bigger than the other.

|  |

| The outside track is longer then the inside one | One solution would be to make one wheel bigger than the other |

Making one wheel bigger than the other is a nice solution as it will actively make the train go around the corner, however the wheels need to be the same size to go in a straight line.

In the early 19th century there were various forms of horse drawn railway and the wheels were held on the track by big flanges. These worked but they would rub against the rails creating friction and making a horrible noise. A neat solution was found, probably by accident when they started casting the wheels. When you cast a wheel it will naturally have a slight slope on it to get it out of the mould.

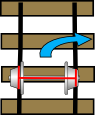

They tried putting the wheels on the axels both ways round. If the wheel is smaller on the outside it means that if the axle moves slightly to the left the wheel is bigger on that side so it steers back onto the track.

|  |

|---|---|

| Wheels sloping outward | Wheels sloping inward |

But if the wheel is bigger on the outside and moves to the left, the axle will turn to the left and quickly fall off the track as you found.

If the track is too sharply curved the cone shape of the wheels can't cope and the flanges of the wheels do rub against the rails making a horrible noise and wearing out the track. Most tracks don't corner this sharply.

If you deliberately push the wheels at an odd angle it can overshoot and take a wobbly swaying path down the rails, this is one reason why old trains often sway gently, though modern suspension is a lot better at coping with this.

- Previous The Nine Dot Challenge!

- Next The Spin of a Bouncing Ball

Comments

I was living near the RR

I was living near the RR tracks for years when a coaltrain would corner it made a screeching sparks flying off the wheels grinding the rusting tracks shinny like new sometime start fires tramendes pressure on tracks !!!

Add a comment