Making graphene industrially

Interview with

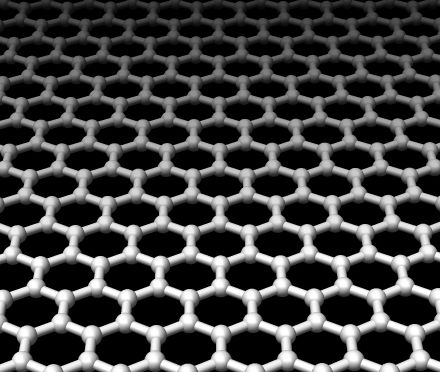

Graphene certainly has some pretty impressive properties, but to harness these features we need to actually make it. Sticky tape is probably not practical for this! So how do we do it? To find out, Amy Goodfellow went to see Catharina Paukner at Cambridge Nanosystems - one company that produces graphene in industrial quantities by breaking apart methane molecules and using the carbon that's released...

features we need to actually make it. Sticky tape is probably not practical for this! So how do we do it? To find out, Amy Goodfellow went to see Catharina Paukner at Cambridge Nanosystems - one company that produces graphene in industrial quantities by breaking apart methane molecules and using the carbon that's released...

Catharina - Graphene is really hard to make on a large scale because this is a single atom layer of carbon. And generally, single atom layers are not very stable and they don't like to exist. We start out with something that's called hydrocarbons or a gas, like methane, the classic greenhouse gas. And we want an all-carbon product so we have to crack it. And the way we do it is we employ a microwave.

Amy - A microwave like I would have at home?

Catharina - The same you would have at home, just a little bit higher powered. You have a power generator, a wave guide and you heat the gas with that wave.

Amy - So, basically, the high energy of this microwave cause these atoms to break apart, and that's how you get your carbon?

Catharina - Yes. Exactly. That's how it is. That's actually the beauty of our process. The only two things we need is electricity and methane. You just think of it as different steps along one way. You have the gas flowing, at one point it breaks, in the next it forms graphene, in the third it gets filtered and then compacted and processed.

Amy - Shall we go and have a look at what's going on? Oh! We get to wear some nice lab coats!

Catharina - So, what we have in here is five of our small-scale reactors.

Amy - These are a lot smaller than I thought. They look like small greenhouses, and in each one there's this sort of about meter long by half a meter in diameter cylinder?

Catharina - These reactors allow us to produce approximately 1 to 2 kilograms of product per day.

Amy - What's actually going on in here?

Catharina - So what we see here is the microwave I was describing earlier. With a slightly more industrial layout than...

Amy - Yeah. This doesn't look anything like a microwave I have at home. It's literally just a silver box. That's all. No window to see your food going round.

Catharina - Not exactly. Yeah. The wave is generated in here and transported through this wave guide. You can see here where the gas is injected. Here is the microwave that cracks it. Then here we have the part that is, the reactor part where graphene is formed.

Amy - So, the cylinder I was describing is just a bit where the graphene actually forms after this cracking has happened?

Catharina - The internal structure is what drives formation of graphene.

Amy - So, it's all going left to right, basically, as we're looking at it?

Catharina - Yes. So, the graphene is formed and transported in the gas stream and sort of filtered out and drops into this hopper, and then hydrogen is emitted through this pipe and goes into an incinerator. So, this is a tiny sample of graphene in a glass pot. You can see it's a very, very low density fly powder.

Amy - Yeah. Because as you shake it around, it sort of almost floats, in a way. It's like one of those toys you have at Christmas where you shake it and it has snowflakes inside.

Catharina - Yeah. It is. It has very low density obviously as you would expect from a single sheet of graphene.

Amy - Yeah. I suppose it doesn't weight very much, does it?

Catharina - It doesn't . So, the amount that you see here would be a approximately 2 grams - maybe one and a half?

Amy - Oh wow! And that's quite a big pot. So, two hundred milliliters weight about 2 grams.

Catharina - Yeah.

Amy - How much would this 200 milliliters be worth?

Catharina - This is sort of our top of the range product, and we sell it mainly for research purposes and for very high-end products. So, we set it at approximately 10 pounds per gram.

Amy - What about the less fancy graphene?

Catharina - We sell different grades of graphene tailored towards the application. Where large-scale applications are required, our carbon we sell it for approximately 45p per gram.

Amy - What's the difference between these two?

Catharina - The different qualities of our material vary in terms of layers, on top of each other. So, while our top range product is sort 70% single layer, the grades as they go down will more have layers - between 10 and 15 in our sort of lowest grade.

Amy - So, if we were looking at some powder of you lowest grade. Would it be a bit less floaty? Compared to this fancy one?

Catharina - It would be slightly denser. Yes.

- Previous Applications of graphene

- Next What is graphene?

Comments

Add a comment