Decreasing the pressure on NGVs

Interview with

Biofuels aren't the only alternative to petrol and diesel. Natural gas is also an  established technology that we know works and, because it contains more hydrogen relative to carbon, the resulting emissions are cleaner. But there's still a catch, as Chris found out from Cambridge University's David Fairen-Jimenez...

established technology that we know works and, because it contains more hydrogen relative to carbon, the resulting emissions are cleaner. But there's still a catch, as Chris found out from Cambridge University's David Fairen-Jimenez...

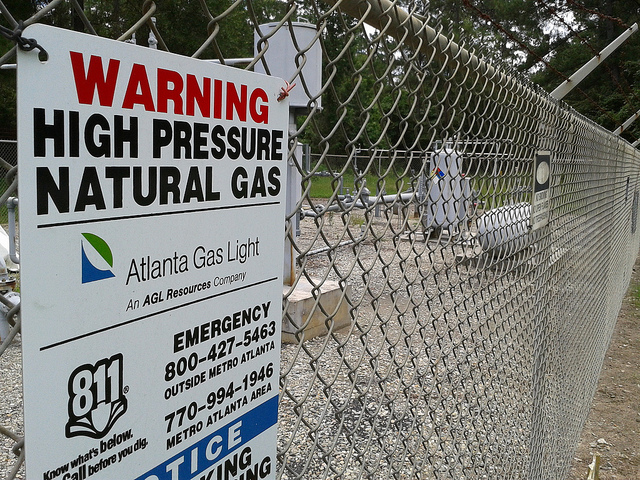

David - So the main problem with using natural gas is that it's a gas not a liquid. So you need to use extremely high pressure in order to store this amount of energy you need for vehicles.

Chris - And why should high pressure be a problem?

David - Well it is related to safety first of all. So if you have a car accident. 200 bar is a really, really high pressure (it's 200 atmospheres of pressure), but it is also quite expensive so we need to use compressors.

Chris - Putting that another way then you're saying that to the store the stuff you need very high pressure cylinders, which they need to be built of strong stuff which weighs a lot, and then just packing the gas in is taking a lot more energy because you're shoving it in under pressure and that adds the cost up?

David - Yes, exactly. And also the main problem is refilling these tanks, it's going to be very difficult. So it's very easy to have just a couple of vehicles that are tending the tanks but if we assume that every single vehicle is using natural gas we will need petrol stations like we have now...

Chris - All equipped with very high pressure...

David - Yes, safety is going to be an extremely big problem and also economics as well.

Chris - And your answer?

David - And the answer is to use an alternative which is based on absorbed natural gas. So basically what we do is using like a porous material in order to be able to store this natural gas as a liquid inside the porosity.

Chris - These materials - they're call MOFs aren't they (metal organic frameworks) - they look like honeycomb I suppose at the nanoscale...

David - Exactly. So we use this nano material which has a microporosity which is on the size of the molecular size. So these really, really tiny holes we have in this material gives extremely high surface areas. We're talking sometimes up to 10,000 square meters in a single gram of the material.

Chris - Right, so you've got a material that's got lots of holes in it and the gas can go into those holes and stick to the sides, stick to the honeycomb I suppose, the surfaces?

David - We have extremely high interactions between the walls of the porosity in these materials and then these gas molecules are stored at much, much lower pressure.

Chris - Are you saying that the structure of the honeycomb, is such that it's got some kind of affinity, or it likes the gas and the gas likes it, so the gas will sort of stick itself on, and that means instead of having to ram the gas in really hard under pressure it just goes in there under much less pressure?

David - Yes, exactly. So the best example to see how the process works is say, when you are having a shower and you have all the vapour from the hot water. It's condensing on the mirror because it's a little bit colder than the rest of the room, so this is exactly the same phenomena.

Chris - You're pulling the gas out of the gas and onto the walls?

David - On the gas face, to the solid face.

Chris - And what materials are they? How do you make the gas stick to this material in this way?

David - Everything is about absorption technologies and about 20 years ago we started using these metal organic frameworks, so really new materials. And we can really tune the properties of these materials from an atomic point of view. So we can really select the building blocks that we have in these materials. We have like a 3D lego that we can create to play with this construct.

Chris - And if you can tweak the chemical formula for them, does that mean you can almost make like a molecular filter where you can chose the chemistry that's going to select for the gas you want, and you could just chuck it in a mixture of gases and it will pull out the one it wants and store it?

David - Yes. exactly. We can improve the absorption capacity of the material or we can improve the selectivity of the material. So we can tune these chemical properties or sometimes even the size, so we may have materials with very tiny porosity, very well defined. Some molecules will be able to got through this porosity, some others will not. This is going to be a molecular sieve.

Chris - And how much gas can one pack into a cylinder which you would fill with this porous material instead of just having an empty space then?

David - The Department of Energy for the United States, for example, they have the targets of storing the same amount of oil that you need to store at 250 bar but at 60 bar, so it's much, much lower pressure but needs to have exactly the same capacity.

Chris - It's still pretty high pressure though, isn't it - 60 atmosphere, 60 bar?

David - 60 bar is also really high but it is really nice in terms of the cost because you don't need to have two stage compressors, you only need to have one single stage compressor, which means that it's much easier to included into petrol stations at the end.

Chris - What's the uptake been like and is there interest from industry to actually deploy this?

David - There are a lot of companies that are very interested in this technology. The first one was BASF, a German company. They started synthesising these materials and you can buy them but they are very expensive right now because they are sold in a very, very low scale. And there are also a lot of spinouts coming out from universities.

Chris - Dare I ask when?

David - It's difficult to know when they are going to start using these materials. But it would be nice to see something in ten years time at least.

- Previous Brilliant biofuels?

- Next Jupiter: The weird planet

Comments

Add a comment