This week scientists from China have identified an environmentally-friendly way of making acrylic acid. Typically, acrylic acid is derived from propylene (so ultimately it comes from crude oil) and over the years it's become a very important industrial material: used in everything from paints, glues, fixing treatments and textiles. More than a billion kilos of the stuff are produced each year for industry.

Weijie Ji and colleagues at Nanjing University have found an efficient way of making it from lactic acid, which most of us know as the acid which makes your muscles ache during exercise. But lactic acid is a better starting material than propylene, because it can readily be made by bacteria in huge vats. Reporting in ACS Catalysis, Ji and his team have cited a new catalyst which allows lactic acid to be converted into acrylic acid at low temperatures. And if you can promote this reaction at low temperatures, then it means less energy (or less expense) is required to keep the reaction going.

Weijie Ji and colleagues at Nanjing University have found an efficient way of making it from lactic acid, which most of us know as the acid which makes your muscles ache during exercise. But lactic acid is a better starting material than propylene, because it can readily be made by bacteria in huge vats. Reporting in ACS Catalysis, Ji and his team have cited a new catalyst which allows lactic acid to be converted into acrylic acid at low temperatures. And if you can promote this reaction at low temperatures, then it means less energy (or less expense) is required to keep the reaction going.

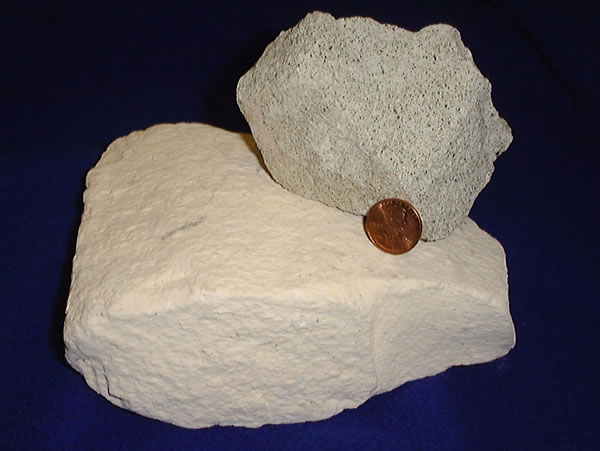

They call the catalyst an NaY zeolite, which means it's because it's a Y-type (called that because of its pore size), sodium absorbent. Cat litter is an example of a zeolite and during the two-stage process, what this one does is to dehydrate the alcohol from the lactic acid (C3H6O3) and produce acrylic acid (C3H4O2).

The zeolite in this case has pores which can hold and exchange sodium cations (Na+) in solution. Now, they actually add some alkali phosphates and reactants to the mix to get it going but what they think is happening is that the catalyst helps release a proton from the lactic acid and helps it react with the reagent, producing acrylic acid with an impressive yield of 58.4%

Comments

Add a comment