Can you 3D-print me a new kidney?

This week, are we on the verge of being able to print a new kidney or liver? And will every home soon have a machine in it to make medicines so we don't need to head off to the chemist for a dose of antibiotics? This is the world of 3D printing and we'll show you what it promises to deliver... Plus, in the news, is fracking contaminating underground water or is it just leaky pipes? And a new breakthrough therapy for multiple sclerosis...

In this episode

00:56 - Fracking not to blame for tainted water

Fracking not to blame for tainted water

with Mark Peplow, Science Writer

Fracking is the controversial technique using high pressured water to extract  natural gasses from deep below the earth's surface. Many have voiced worries that fracking can contaminate local water supplies with gasses like methane. A recent study has suggested this might not be down to fracking itself, but to poorly built wells at the sites. Science writer Mark Peplow told Chris Smith the details of the study...

natural gasses from deep below the earth's surface. Many have voiced worries that fracking can contaminate local water supplies with gasses like methane. A recent study has suggested this might not be down to fracking itself, but to poorly built wells at the sites. Science writer Mark Peplow told Chris Smith the details of the study...

Mark - The point is, this means that the fracking process isn't to blame for any methane contamination. It's the result of poor workmanship at the borehole. And then that borehole is lined with steel and concrete to stop the gas escaping as it rises through the pipe. The key thing is, that suggests that it should be possible to eliminate the leakage by simply doing a proper job. What it does highlight is that you need really strong regulations to insure that the wells are constructed properly.

Chris - How did they do this sort of methane post-mortem?

Mark - It's absolutely fantastic. They used a really clever bit of chemical analysis to work out where the methane in their samples have come from. So, the first step is to look at the ratio with methane and ethane in the water to see if it matches the gas in the shale.

Chris - So, ethane and methane are both found underground, are they?

Mark - Yes, they are. Natural gas that comes through your cooker is methane, but in gas deposits, you tend to get some heavier hydrocarbons as well which are still gases, such as ethane. What you do is you just see if it matches up. But the trouble is, those ratios can be altered by microbes or by chemical reactions with oxygen, so you need another way of looking at this. So, they looked at the ratios of gases like helium and neon, and argon. Now, these are noble gases - so-called because they're very unreactive, so they're not altered by biological chemical processes. Each shale region has a characteristic makeup with all these gases, its chemical fingerprint. Crucially, that fingerprint does change in a predictable way at various stages of the process as the gas is dissolved in fracking fluid, as it moves through the borehole, and as it gets into aquifers. So, you look at these fingerprints and you can effectively map out where the gas just flowed before it got into the water wells. And they looked at 130 wells in Pennsylvania and Texas and found 8 clusters of wells near shale gas sites where there had been leakage through the borehole casing, but not directly from the fracked shale beneath.

Chris - Good grief, so you can actually tell at what point in the underground journey the gas is taking it has exited from the fracking operation and actually got into the groundwater supply.

Mark - Yeah, that's right.

Chris - That's pretty impressive. That obviously now fingers that particularly bit of engineering so, a.) is there a blame attached to this now, are we looking at legal cases? And b.) can this be remedied or rectified, now the fracking operations in those places are in situ?

Mark - There is a legal case ongoing in Texas that this might have some impact on. in terms of rectifying it, yes, they can be rectified. But obviously, what needs to be done is to have the proper regulations in place to make sure that this is done properly in the first instance.

Chris - Would the regulations in place here in Britain have stopped that sort of poor infrastructure being used which is causing this problem in America?

Mark - I think that's impossible to know. Certainly, advocates for fracking, say, that "of course, nothing like that would happen over here". It's very difficult to know because things are moving more slowly over here than they did do in the US, and because there's such a focus of public attention on the issue, I suspect that any regulator would be down on dodgy operators like a ton of bricks. So in a sense, the public furore about it, may actually help to insure that if fracking does move forward, regulators keep a very careful eye on it to make sure that these wells are created in the right way.

Chris - And worst case scenario, say it does happen. The presence of methane and a bit of ethane in people's water, does it pose a threat to people?

Mark - Probably not, but there really isn't enough literature yet out there to know for sure. Of course, it's something that naturally concerns people. When you're losing methane out of your well, it's actually a major problem if it's escaping into the atmosphere. There's been a lot of talk actually about how shale gas is a good thing for tackling climate change because it burns cleaner than coal, it doesn't produce as much carbon dioxide emissions. But if you're allowing methane to leak from your well, methane is a much, much more powerful greenhouse gas than carbon dioxide. So, if you've got a leaky shale gas operation, that could actually be worse in terms of climate change than burning coal.

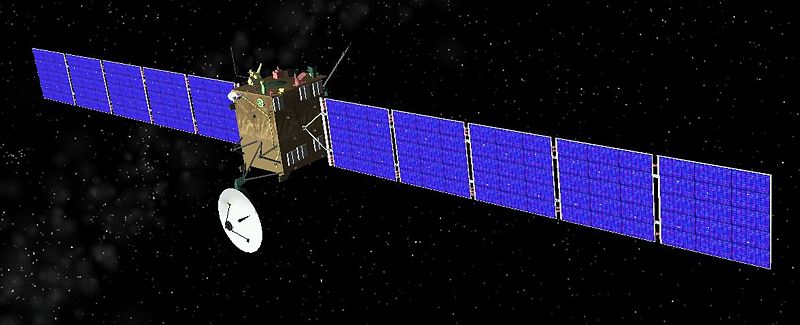

06:08 - Rosetta comet landing site spotted

Rosetta comet landing site spotted

with Ian Wright, Department of Physical Sciences at The Open University

The team behind the comet chaser Rosetta, which is in hot pursuit of a comet  over 400 million kilometers away, are currently making plans to send a smaller probe, called Philae, to actually land on its surface. To explain how you would go about doing this, and what the surface of the comet might teach us, Kat Arney spoke to Professor Ian Wright...

over 400 million kilometers away, are currently making plans to send a smaller probe, called Philae, to actually land on its surface. To explain how you would go about doing this, and what the surface of the comet might teach us, Kat Arney spoke to Professor Ian Wright...

Ian - Earlier in the year, we did a practice of this where we took some data that we imagined we might get. And then we sat around and worked out how we would do it. the whole point of the practice was to find out what limitations of the process were and so on and so forth. Of course, you can probably imagine that the shape model we were using at that point looks nothing like the body that it turned out to be. That has been a surprise to us.

Kat - So, you didn't know what the comet actually looked like close up until you could get close enough to really photograph it.

Ian - Absolutely right. we've been using a couple of different shape models that have been produced over the years. But they're what you might call potato-shaped rather than this rubber duck shape. So, that has put some tremendously interesting constraints on the mission in terms of flight dynamics and all that jazz. But there are two aspects really to selecting the landing site. We can look at the images and we can pour over those all day long and the scientists can say, "This area looks interesting, that one looks exciting" and all that sort of stuff. But we have to factor in other aspects of this. Is the area even reachable with the orbital constraints that we've got? We have to worry about illumination. We don't want too much and we don't want too little. Too much and we get too hot and too little you don't charge the solar panels up. Of course, at any one instant, we've got to be able to communicate from the lander back to the orbiter. And obviously, we want to land on something that's reasonably doable. So, something that's reasonably flat, should we say as opposed to vertiginous. The whole thing hereon is being controlled by the mission engineers and so on and if, for whatever reasons the comet suddenly becomes violently active, we may have to take evasive action.

Kat - When are you going to release the lander or are you waiting for just the right moment?

Ian - There will be absolutely a date and time when it's scheduled to happen. It is currently pencilled in for November the 11th, but I think a decision will be made towards the end of September to either clarify that or change it. There are just huge amounts of work to do from the mission dynamics point of view.

Kat - Assuming that the lander does make it safely onto the surface of the comet, what sort of experiments is it going to be doing there? What's it looking for?

Ian - There are about 10 experiments, 10 instruments on the lander. There are cameras, there's a drilling system, there's an instrument like my own which is what is known as a gas chromatograph mass spectrometer. To explain that, it's a miniaturised analytical laboratory where we will take in samples and heat them up and then find out what the comet is made out of. There are devices which will determine the physical properties of the surface, how hard it is. There's a microphone to listen to any dust articles raining down. There are various sensors in the feet to determine temperatures, and so on and so forth. There's just a whole range of different instruments on there.

Kat - It must be an incredible feeling to be involved in this because I can remember looking up in the sky, there's been a couple of comets I think in my living memory that have been up and we've seen them. But then to think that there's actually - we've sent something up to a comet and we can now land on it. That's an incredible achievement to even get this far, isn't it?

Ian - I've been working on this for over 20 years. I can't say I've been working on it full time for 20 years, but it's never been far away over that period of time. So yes, we're excited but also, this is the end of a very long, hard, slog and we're looking forward hopefully to a successful outcome. I must admit in my lifetime, I've looked up in the sky at some fairly duff comets. Every comet of the century turns out to be not that interesting or not that exciting. So, this is a different kind of reward I think.

11:02 - New treatment breakthrough for MS

New treatment breakthrough for MS

with Su Metcalfe, The University of Cambridge

Multiple sclerosis is a chronic disease causing the nervous system to inflame, and one of the most common causes of disability in young adults. Merck Serono have awarded Su Metcalfe a million pound grant to start trials of a new, nanoparticle treatment. She explained more to Chris Smith...

one of the most common causes of disability in young adults. Merck Serono have awarded Su Metcalfe a million pound grant to start trials of a new, nanoparticle treatment. She explained more to Chris Smith...

Su - The disease that we're working on is multiple sclerosis and this is where the immune cells actually attack yourself - the brain and the spinal cord. All the treatments today are involving suppressing the immune response. These are the active cells that are attacking the nerve cells. But underneath this, there's also - once the nerves are damaged, they can't be repaired.

Chris - How are you trying to tackle it with your work?

Su - We've prepared a natural repair factor that occurs in the body, but we've placed it inside a kind of magic bullet so we can target this factor to the damaged areas of the nerves. The magic bullet then releases slowly the factor that's going to repair those nerves over a period of time. So, it's going to help repair the nerve and at the same time, it's going to help reduce the immune response against the nerve.

Chris - If we could look at each of those things in turn then, first of all, what is the repair factor? How does that work?

Su - This is a factor called LIF or Leukaemia Inhibitory Factor which is a stem cell factor and it's been discovered very recently that it does repair nerves.

Chris - How does it work?

Su - It's not known, but we think it's stopping the inflammation that's associated with damage to the nerve and allows repair cells to actually go in and recreate the functional nerve.

Chris - These stem cells are already in the brain or the part of the nervous system but they're not necessarily switched on or functional to repair the damage. You're saying you put this factor in and not only does it damp down the inflammation, but it can also stimulate those stem cells to do a repair process.

Su - That's exactly the process, yes.

Chris - And now, tell us the other aspect of what you're describing which is the magic bullet - you've got to deliver this LIF factor in somehow. How are you doing that?

Su - We're placing the LIF factor inside the same material that if anyone has had stitches for an operation, they have these soluble stitches which gradually dissolve. So, we're using that same material, but making the material extremely small so you get tiny, tiny particles. And we have the factor embedded in the material. On the outside, we can put a target molecule which will carry those tiny nanoparticles directly to the nerves that are damaged.

Chris - How do you get the particles to where they're needed in the body? Do you have to inject them?

Su - To start with, we'll be injecting them. But also, we are able to take the particles through a nasal spray and they will crossover into the brain at the back of the nose. There's normally a barrier that protects the brain, but the one place there is no barrier is just behind the nose.

Chris - Once they get into the brain, how do they know where to go? How do they know where the damage is occurring because of the MS so they have to target that area or do they just go everywhere?

Su - Essentially, they will flow into the brain, but they have a sticky molecule on the surface that will recognise the places that are damaged. And so, they will then start to pile up on those damaged areas and release the factor LIF.

Chris - What is the sticky molecule that enables you to target these particles to the right place in the brain?

Su - We attach to the surface of the particles something called an antibody which is specific for only certain cells in the brain and these are the cells that can repair the damage.

Chris - So, you deliver the particle either through the nasal spray or in the blood. The antibody on the surface enables them to home in to the right place in the nervous system where the inflammation and damage is occurring. They then ooze out this LIF factor then what happens?

Su - Then the factor will act on those cells that are able to repair the nerves and cause them to switch on and start their repair.

Chris - Have you got data in people that this works?

Su - No, we haven't done it yet in people. We have done it in mice and we showed that this works.

Chris - Will you now be taking this into a clinical trial to see if you can achieve the same effect in people?

Su - The funding award is to take this into pre-clinical trials which we need to do before we can go into people and that will take about perhaps two years.

16:07 - Why your face stands out from the crowd

Why your face stands out from the crowd

with Michael Sheehan, University of California

Take a long, hard look in the mirror. Unless you are an identical twin your face is  one of a kind, which is the main way your friends and family can recognise you. But why do humans have such variation across faces compared to other animals? Michael Sheehan looked at US army data to discover whether our faces really are so different...

one of a kind, which is the main way your friends and family can recognise you. But why do humans have such variation across faces compared to other animals? Michael Sheehan looked at US army data to discover whether our faces really are so different...

Michael - One of the things that I think is really striking about humans is, as we look around at people, we notice that they're all really variable. We use that variation to tell each other apart and to recognise who's who in our social interactions. It's particularly interesting especially when you compare humans to other animals that you see as you walk around that we seem strikingly much more variable than a lot of the species we see. We also have really complex social interactions which suggests that given that we use the variation for recognition that maybe there's something about our social interactions that may have sort of driven our morphology to be much more recognisable. And so, we're interested in looking to see whether there was any evidence that our social interactions and being recognisable may have shaped our faces over evolutionary time. What's really quite striking as well is that our faces are very variable but the rest of our bodies aren't necessarily as strikingly variable necessarily. We used a US army database for they measured lots of different - both facial and the rest of the body - morphology of service members with a wide range of ages and ethnicities. When we do that for both men and women in all cases we examined faces were variable both in the sense that the traits in the face turned higher levels of variability, but also I think quite strikingly, the traits in the face are less correlated with each other. So essentially, what that means is that even though tall people have long arms and long legs, and sort of all the parts of their body are generally bigger, they don't necessarily have bigger facial traits. And so, it's not the case that individuals with large noses necessarily have widely spaced eyes. The fact that you can mix and match different sizes of facial traits together, it's a huge range of combinatorial variation that ends up making people very unique looking.

Georgia - Why is there so much variation across our faces and not amongst our other body parts?

Michael - So the hypothesis we were working with is that in the case of humans, we use faces as one of the main things we use to recognise individuals. So, I think from anyone's own experience in life, you know that being able to recognise who you're interacting with is really important. And so, the idea in this case that we're arguing is that there may have been some selection on facial traits to be more recognisable, given that that is the trait that we happen to use for recognition.

Georgia - So, how does having a recognisable face actually help you?

Michael - The really basic idea is that in many situations, it can be costly to be confused with other individuals. It could be that you get some aggression or punishment that's actually meant for someone else. But because you look like them, it ends up going to you. The other reason that it could be costly to be confused with other individuals is that if you did something really great, you want to get all the rewards or the benefits of doing that, then if someone else looks like you, they may in fact get whatever prize or reward that you may have gotten. In an evolutionary sense, you can imagine that if you're sort of the hot shot, that maybe there is - you're going to get some resource that someone else wouldn't get or a mating or something like that, you could potentially lose out on if there's confusion about who actually did the great deed.

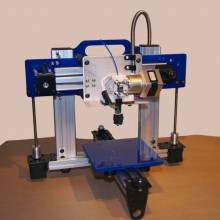

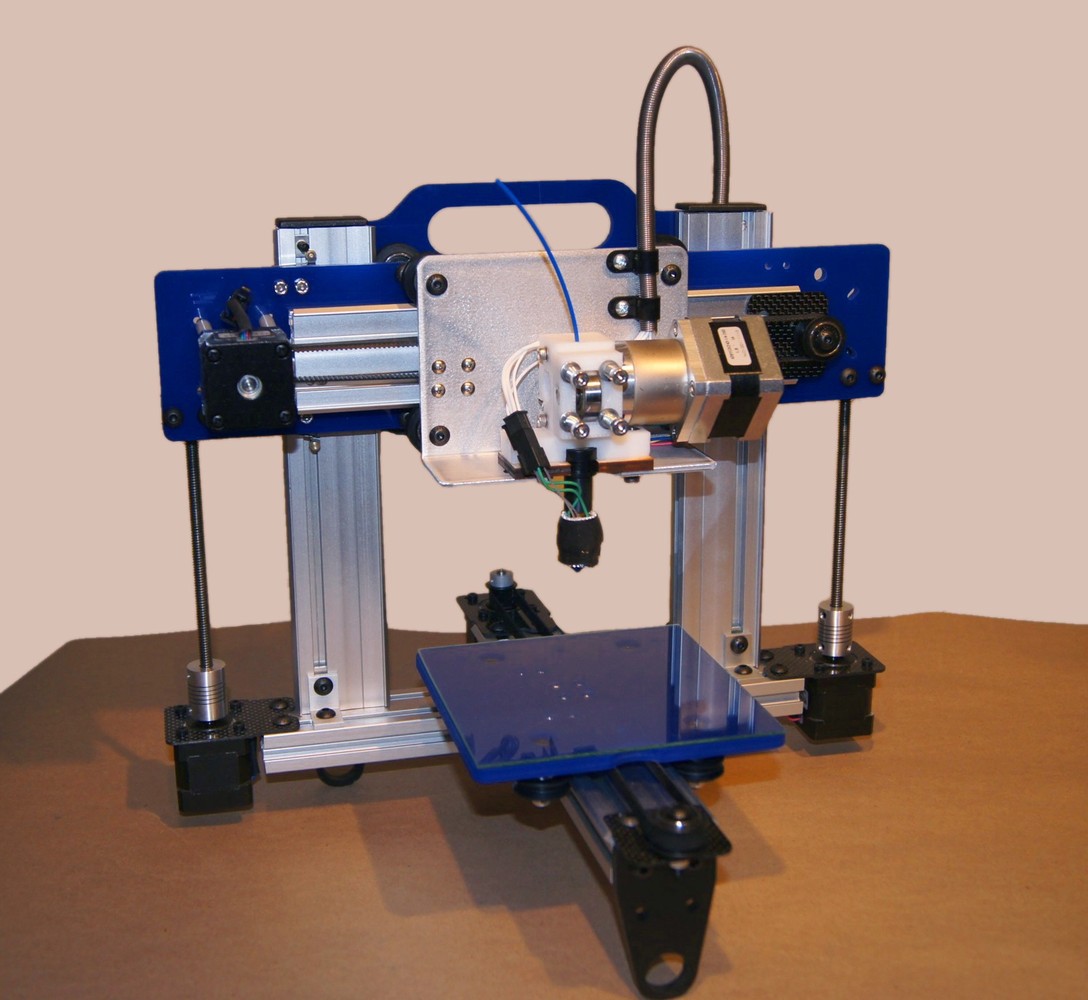

19:55 - What is 3D printing?

What is 3D printing?

with Tim Minshall, University of Cambridge

With news of 3D printed cars, houses and even food, is this the future of  manufacturing? We take a closer look at the workings of 3D printing, also known as additive manufacturing, and what this might mean for our collective futures. Tim Minshall took Kat Arney through the basics...

manufacturing? We take a closer look at the workings of 3D printing, also known as additive manufacturing, and what this might mean for our collective futures. Tim Minshall took Kat Arney through the basics...

Tim - This is an additive process. The alternative ones are subtractive and formative. So, we have a block of wood and you take stuff off it. Formative is when you have a piece of material and you squish it into the right shape. But 3D printing or additive manufacturing literally is additive. You start off with nothing and you build something up layer by layer. Perhaps a way of thinking about this is to remember back to primary school. When you first did pottery, you were maybe given a blob of clay and told you to make something. The way you did it was, you got little bits of the clay and you rolled it out into a little worm shape and you joined the ends up and you put a circle down and then you did the same again. You built up a little cup or a little vase which you proudly took home. So, that's an additive layer process and that's what 3D printing basically is. It's got 2 broad types. One when you're working in a liquid form. And one where you're working in a powder form. So, the liquid one is you're either squirting something out of a tube like a hot glue gun and you build up the shape layer by layer that way or you start off with a vase of liquid and you use an ultraviolet laser to selectively make it go solid in the places you want layer by layer. The alternative way is using powders. So, metal powders, ceramic powders, plastic powders. The way to think of that one is, imagine if I poured dry sand onto the table and then squirted some glue into a circle shape and then blew the dry sand away. You'd be left with a layer of a solid object. You put more sand down, more glue on top of that and blew the sand away again, you'd slowly build up the object.

Kat - People may be most familiar with some of the 3D printers that are coming into our homes that use various types of plastics and things like that. We've had a Tweet from our listener Simon Archer who says, "What kinds of materials can we do 3D printing with?"

Tim - So, the main materials are plastics, but also, ceramics and metals can be used. A particularly interesting area is when you have multiple materials.

Kat - We've had a tweet from our listener Ed Wilson and he says, "Are multi-material structures possible?" How can you do more than one type of material in a printer?

Tim - It's very clever - this. So, the idea is that you have conductive metal track inside a piece of material being produced. In plastics, you'd have to have multiple nozzles at work there and some very clever, very challenging technological barriers that need to be overcome there. But the dream is, you could then print things such as a component for an aircraft with strain sensors built into it. You could have electrical conductors built into objects that are made out of plastic, but we're a little way off that at the moment.

Kat - Some of the things you hear about, they seem like they're replicated from Star Trek where you just put it in and like, bingo! Here's Sunday lunch. But in a more realistic, perhaps now, we're in the very near future, what are some of the main applications of 3D printing technology? Where are they going?

Tim - Well, maybe just to give a tiny bit of background, it's gone through broadly 3 phases. We started off making models and prototypes and that's still a big part of 3D printing. You make a replica of the thing you want. If you're making a new phone or a new drill or something, you make it as a model to see what it would look like before making it in the normal way. Then we moved on to making moulds. So at the moment, if you want to make your Lego bricks or mobile phone plastic case, you'd make a mould and then make lots and lots of identical model versions of it using plastic. The cost of those moulds is very, very high in the process of making them quite slow. With 3D printing, you can actually print these moulds much cheaper and much faster. But the exciting bit and I think this is where people have got really interested is the fact you can produce now the finished, final part of the thing you want. In particular, interesting areas there are in medicine, aerospace, and automotive.

Kat - And so for example, just to give me a really quick example, we saw a recent story where a child had had a vertebra printed. Is that a really growing area of these replacement prosthesis?

Tim - Medicine really does seem to be taking off and there are three broad areas. One is, replacing missing limbs and some very exciting area is the low cost area. If anybody has a moment to go and look at websites where they talk about project Daniel or Robohand on YouTube, really interesting projects there. We also see hearing aids being printed in this way that go in your ear. There's then implants so surgeons actually producing replacement - for example for a severe injury to the face. They can produce part of your face, exactly as it was before. The third area of medicine, is around producing a living part of the body. So, it's either stuff you attach to the body, stuff you insert in the body, or stuff that's in the body to grow.

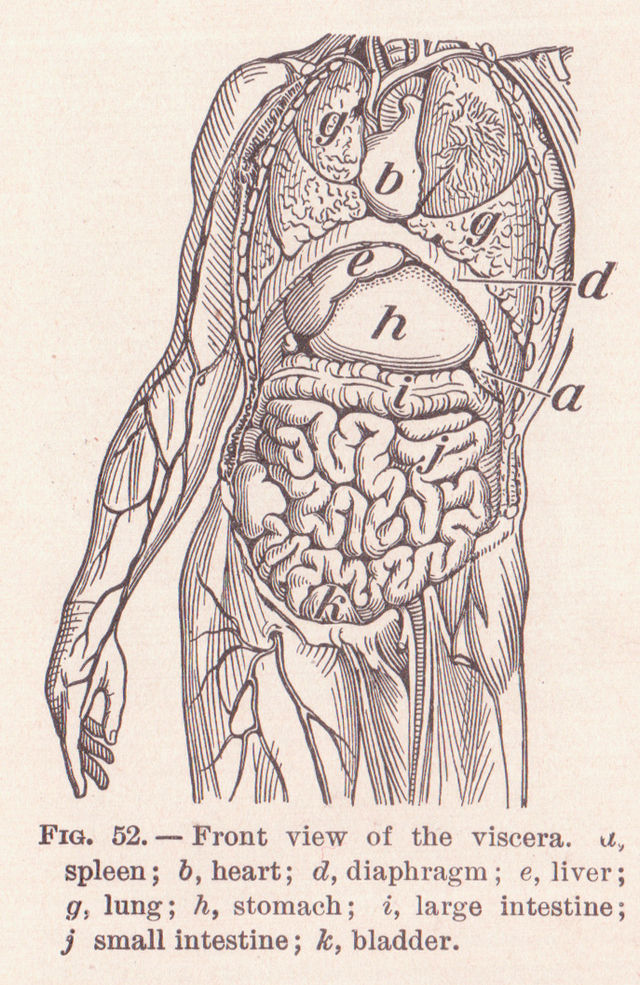

25:20 - Could you 3D print a spare kidney?

Could you 3D print a spare kidney?

with Michael Molinari, OxSyBio

Will it ever be possible to 3D print human tissue to build up a working organ?  Michael Molinari is the director of OxSyBio, a company aiming to do just this, which could maybe one day be a way of providing replacement livers or even a heart to people that need them. He spoke to Chris Smith...

Michael Molinari is the director of OxSyBio, a company aiming to do just this, which could maybe one day be a way of providing replacement livers or even a heart to people that need them. He spoke to Chris Smith...

Michael - Yes, and one of the ways that I like to think about it is that an organ is really like a three-dimensional town and the cells are people and they all live in houses supplied with all of the mod-cons that they need to keep them happy. And at the same time, you've got a road network of blood vessels that are running around delivering groceries and other nutrients to the cells and keeping them happy. And so when you compare that to printing a solid block of plastic or metal that you might use for an aircraft, it's a fantastically more complicated process. I can't sit here and say that's something we're going to be able to deliver tomorrow, and there are a lot of challenges that we need to address to get there but it is a very exciting area.

Chris - What can you deliver right now?

Michael - We're at the moment concentrating on printing sort of networks of cells that are encapsulated in droplets. One way of thinking about it is a three-dimensional network of bubble wrap and in each of those bubbles we have certain cells, we and the cells can dissolve away the bubble wrap and leave you with a functioning network of cells.

Chris - So this would be for something like if someone needed a new kidney. You could design a way of depositing the bubble wrap with the appropriate kidney cells invested in the bubble wrap, build up a kidney with all the right cell types and the right tubes connected to the right places. Dissolve away the bubble wrap and then you would potentially have something that could do the job of a kidney.

Michael - Yes. The key word there is "Potentially" and we are at a very early stage. The best estimates are that it will be ten plus years away before we can print, I think, a human heart was the last estimate or a piece of heart that you might be able to use in surgery. But that's certainly the long-term goal is to be able to deliver that, to deliver an organ or a part of an organ that could be used by surgeons.

Chris - A couple of challenges here. I mean, one must be, if we look at a part of the body. It's not just made of cells. There's the matrix, the things that support the cells there. There are blood vessels, nerves, and so on. In the same way as a microchip has got wires and other things connecting it on to the motherboard, for example. So, you have to overcome the problem, not just of depositing this matrix and making the environment, the houses nice but you then got to keep the people who are going to live in the houses, the cells, you got to keep them happy as well, haven't you? So that's sort of two levels of complexity.

Michael - It is, and one of the challenges at the moment is keeping the cells happy and the approach that we're using of delivering them effectively in bubble wrap is that we're protecting them through the printing process and keeping them happy. And one of the key elements to the process to understand is that like people, cells over time make themselves comfortable and will actually produce matrix around themselves to make them happy. So, they'll buy in their toaster and their foot spa. And so, it's a little bit of an interplay between those two factors. So you need to keep them happy when you give them their new home and then allow them the time to develop all the structures and the matrix around them that's going to allow them to function normally.

Chris - My brain is just sort of generating images of your kidneys sort of playing with its X-Box and popping the toaster down and bathing it's feet in the foot spa. Won't aske what's actually in the foot spa, especially if it was a kidney, but the point is, where would you get the cells from? Would they come from the individual? So if I needed a kidney, is the idea here that you could take some of my stem cells and then turn them into kidney cells and then use those in your printing process to make me a bio-compatible genetically compatible organ?

Michael - Potentially. The field is still at an early stage of development and so all of the focus at the moment is coming up with the techniques that let us deliver cells and keep them happy and make them function normally. One of the benefits, potentially, of this approach to printing organs for the surgery that you'd be able to have them off the shelf and if you are taking cells from an individual patient and then printing them and growing them, it would take time. So, the long-term ideal goal would be if we could use generic stem cells and print using them and literally have an organ off the shelf. It's a long way away and I think over the coming years, as we address some of the basic challenges, strategies to cover that will emerge.

30:05 - Printing parts for planes

Printing parts for planes

with Martin Rawson, Rolls-Royce

Next time you go on holiday, chances are a jet engine will help you to get  there. These engines usually have a large fan at the front end - driven by engine - that pushes air backwards, propelling the plane forwards.

there. These engines usually have a large fan at the front end - driven by engine - that pushes air backwards, propelling the plane forwards.

The blades of these fans are precision-engineered to give them the very great strength and durability that they need to work reliably and safely. But this also makes them very expensive to manufacture and replace.

Engineers at the UK company Rolls-Royce have come up with a solution that means they can use a technique similar to 3D printing, to repair and strengthen worn fan blades. Graihagh Jackson spoke to Rolls-Royce engineer Martin Rawson to hear how it works...

Martin - So you could repair certainly aerofoils which are the rotating parts of the blades. The powder's delivered to a point above the aerofoil surface where you want to deposit the material and then you essentially use a laser beam to melt the powder as it arrives at that position. You can build those back up to their original shape, so you've got the original blade profile.

Graihagh - So why would you use this method over melting something down and starting from scratch?

Martin - One of the advantages of powder is that, of course, you can potentially take subtle difference in composition of powder and tailor them metallurgically to where they're most appropriate. So, you could also potentially in the rotating discs where you've got the sort of the outer of the rim of the disc which carries the blades is a lot hotter, for example, than the bore of the disc. So again you could look at changing the composition.

Graihagh - In the future, what sort of applications are we looking at?

Martin - I was in the AeroMat conference a few years ago where certainly NASA were interested in the use of powders for either building structures in space or for, I guess again, repairing components in space. They seem very interested in the technology, you know. The fact it was transportable. You could easily transport the powder, you could easily transport the machines. In terms of Rolls-Royce, so, prototype applications, development engines. I could see that things like 3D printing would have a real future in that sort of area. If you look back a number of years where we were using TIG welding techniques to actually build up components for the prototypes for development engines. That was a big benefit considering that to actually obtain the casting from a traditional route would take something like 12 months. So, I suppose, your imagination's the limits on that one in terms of what you could do.

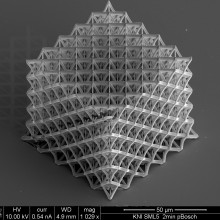

33:31 - Making a brick as light as a feather

Making a brick as light as a feather

with Julia Greer, California Institute of Technology

As a general rule, materials that are strong also tend to be heavy. And, in the  case of an aeroplane for instance, more weight means more fuel being burned and that means higher running costs. So California Institute of Technology scientist Julia Greer is using 3D printing to produce new materials with shapes and structures that make them super strong but also extremely light. She explained the bright future of this technology to Kat Arney...

case of an aeroplane for instance, more weight means more fuel being burned and that means higher running costs. So California Institute of Technology scientist Julia Greer is using 3D printing to produce new materials with shapes and structures that make them super strong but also extremely light. She explained the bright future of this technology to Kat Arney...

Julia - The technology that we're using is called, Two-photon Lithography. It's a little bit like 3D printing but it's able to generate features that are much smaller in size. So, what we're doing is we're using this two-photon lithography process to write an open cell's structures in a polymer, and then we coat these polymer's scaffolds with a different material, and then we dissolve the initial polymer matrix. So, in a way, it's a sacrificial scaffold that we get rid of at the end and so the final structures are very, very light weight. But because the wall thickness in these structures is at the nanometre level, we are able to also control its strength. And so, we are able to make materials that are both really strong and really light-weight.

Kat - I'm kind of imagining here almost a, you know, lattice structure. Maybe like the structure of the Eiffel tower. You make that in polymer and then you coat it with these tiny, tiny nanoparticles to build these very strong structures. Is that basically what you're doing?

Julia - It's very close. You got it nearly right on. The only thing is that we don't coat it with nanoparticles, instead we coat it with a continuous conformal thin film. So imagine a two-dimensional nanoribbon, so to speak, and you wrap it around a three-dimensional architecture and then you remove whatever was on the inside so that you build a hollow Eiffel tower. So, it's effectively an Eiffel where each individual strut itself is a pipe.

Kat - Now we know for something like the Eiffel tower, that's a very light structure 'cause it's full of holes but is also pretty strong. What sort of things could you use these materials for? How strong are they?

Julia - Well. You tell me. So, imagine a brick made out of our nanotrusses. When it sits on your hand, it looks like a brick, it smells like a brick but if you drop it up in the air, it's going to fall slower than a feather. But at the same time it's going to be just as strong as steel or a ceramic. So, you can use these for building blocks where, for example, if you need propel something up in space. You would really appreciate having the low weight but at the same time the material has to be strong enough to be able to withstand the pressure from the vacuum. So, any kind of an application where you have to propel things up in the air or up into space, or a bridge for example. Or something where the weight is of essence but the strength is still required, they would be really good for. As well as they're also damage-tolerant. So, it's very hard to tear them apart, for example, or to break it. So, for any kind of a cushioning application where you need to protect a sensitive device. So as a foam or as a wrapping paper, that would work really well too.

Kat - We've just heard from some people who are using this kind of printing technology to repair jet engines. But obviously, jet planes are really, really heavy and an enormous amount of fuel is burned just getting the jet across the Atlantic, regardless of the passengers and the payload. So, could this technology, for example, make air travel a lot cheaper or certainly use a lot less fuel?

Julia - That is exactly right. So, if we were to incorporate these nanotrusses in this skin on an airplane. Even if we were to replace 50% of what is currently being used with these materials, I think we can benefit tremendously from the cost savings in fuel. So, even a small reduction in the weight of the airplane would already facilitate a tremendous reduction in the price of the fuel that it takes to propel these very heavy machines through the air. So, our materials right now, we can't fabricate them in large quantities but if we could make sheets of paper out of them. And our vision is that we would be able to effectively roll-to-roll print these like paper towels. We can use this for the airplane's skin and wrap it around the airplane and thereby make the airplanes a lot lighter. One very neat thing about this technology is that these nanotruss materials can be made of just about any material that's available. So, it could be a ceramic, it could be a metal, it could be a semi-conductor. So, for these high-temperature applications, of course in the jet engines, it's very hot. We can use ceramics and they're generally very robust to high temperature and so we can make these nearly hollow ceramics that are robust to high temperature and robust to mechanical damage and incorporate them as part of the jet engines, and thereby we would significantly reduce the weight of the airplane without having to sacrifice any other properties like the ability to withstand high temperatures and damage tolerance.

Kat - That does sound absolutely fantastic but how close to reality is this? How soon do you think you could see these types of materials, perhaps even becoming used in commercial applications?

Julia - Oh, I think it's going to be within the next maybe year or two. We're actually very close to being able to produce these in quantities. The major road block right now is the writing of the polymer matrix. The step where you deposit a conformal coating, effectively the nano ribbon I was describing, of another material, a thin film of material, and then the subsequent removal of the initial polymer scaffold. Those technologies already exist today, so they wouldn't be show stoppers at all. It's the writing process and the two-photon lithography itself is a relatively slow process. So, we're working on developing a somewhat different technology that would enable us to quickly generate these patterns and they don't have to be just as complex, as long as we can do it quickly. So, we're looking at other technologies and pairing up with several companies to try to identify what would make the most sense but our vision is to try to roll-to-roll print them so we can generate sheets of these materials which can then possibly be laminated or somehow stacked together to make larger three-dimensional structures.

40:03 - Printing out your own pain killers

Printing out your own pain killers

with Lee Cronin, University of Glasgow

3D-printing is set to revolutionise the way we do chemistry, and could lead to  pharmacies printing out our drugs when we need them, or even home printed prescriptions. Lee Cronin is the Regius Professor of Chemistry at Glasgow University...

pharmacies printing out our drugs when we need them, or even home printed prescriptions. Lee Cronin is the Regius Professor of Chemistry at Glasgow University...

Lee - I wanted to see if we could take a cheap robot, a bit like a 3D printer, and use it to automate chemistry. So, one of the problems we're having in chemistry is that only certain cooks can make certain recipes and get certain tastes, and what we wanted to do is make all recipes and all tastes available to everyone. By using a 3D printer which is really cheap and becoming very available, we could use a 3D printer in two different ways. First way, is that we use it to print a plastic object or material objects, in this case, like a test tube in which you do your chemistry. Then the 3D printer switches function and turns from test tube printing to actually moving liquids around a bit like an automatic cocktail maker in which you would add the chemicals into the test tube it's just made to allow the chemical reaction to go. And because a 3D printer would know which order to add to the chemicals, it would be very precise and allow us to replicate our chemistry recipe and allow the thing to work in many different places and situations.

Chris - And this would get around the fact that some cooks are better than others. It may not be perfectly replicated by another person but a machine would follow those instructions to perfection time and time again.

Lee - Exactly. So, there are a number of features that come with that. If we could add chemistry into the software, we could beam chemistry around the world. We could overcome drug counterfeiting. And we could also make many, many drugs or molecules available than are available right now because you have to use big manufacturing facilities. In essence, it democratises chemistry in a new way.

Chris - Where would you see this having an application?

Lee - The first thing that we're trying to look at here is trying to go for drug-like molecules or diagnostic systems where we can use them to treat and diagnose people's health issues. That seems to be a really compelling idea because one of the biggest problems in the world right now is having access to medicine. And if we can allow the system to make different medicines, then, say a person has a certain condition but they know that one particular drug doesn't really work for them but another drug that's maybe rarer or not so available is better to treat them. Then they could simply dial that up instead, and this allows us to personalize the medical process in a slightly different way. So, you have a bit more choice.

Chris - Do you see this having both a domestic and a commercial/academic use? Because I can see how the same phenomenon would apply in my house. I mean, if I knew that I was going to need X dose of antibiotics, rather than go to the chemist, I could get a prescription from you, you know. Say you're my doctor, and I would feed this into my machine and it would effectively... the prescription's like a license to produce a certain amount of a molecule for a certain period of time. I could have a home 3D printer that would make my antibiotics for me for the period of time for which I should be taking them.

Lee - Yeah. Exactly. Now I mean that's a very long-term view. What we want to do first of all is to use it as a research and development tool. One of the biggest problems we have is in science is collaboration. We want to be able to take our recipes and perfect them anywhere in the world. So, maybe in my lab I discover a new molecule. I want to give it to the colleagues in Australia. It may take them two or three months to get the recipe right. However, if they have the 3D printer robot they would just download my code and it would work tomorrow. So, then they could the experiments they need. So, that's research level idea. Take it to a next level - the local pharmacy where you go to your doctor, your doctor would work out what particular condition you have and the special drugs that you need, would send prescription to a local pharmacy where they have this device, and they would produce them for you, and you'd got to the pharmacy and collect it. Then in years further, then it might get to the point where it's in your house and you then, like you say, have a prescription. And you could then have license to have access to that molecule. And so this then changes the game and ensures that people have access to high quality, diverse number of different molecules. The other thing is if you're a patient that has many ailments, you've got to remember what order to take your pills or you need a particular formulation for the day. Maybe we can think of a system that would actually mix the ingredients you need for that particular day or time, so you're not confused and take the wrong pills.

44:34 - The 3D-printed fruit factory

The 3D-printed fruit factory

with Vaiva Kalnikaita and Gabriel Villar, Dovetailed

Hexagonal honeyberries, strawberry and cream flavoured berries and even pina colada fruit. This isn't a juicy sequel to Charlie and the Chocolate Factory, but some of the creations that Cambridge based company Dovetailed have been making with their 3D printer. Georgia Mills went to speak to the founder, Vaiva Kalnikaita and chief inventor, Gabriel Villar and see the fruits of their labour....

Vaiva - The way it works it prints individual little liquids and encapsulates it in a thin gel membrane and it can control every single droplet for texture, for flavour, for colour, and you can build really intricate and interesting structures with it.

Georgia - Great. So, what sort of things have you been using this for?

Vaiva - So, we've been printing very successfully, raspberries, but more interestingly, we've been inventing new fruit that don't exist in nature yet. So, we've been printing honey berries, a popular dessert called strawberries and cream. Instead of having strawberries and cream separately, we printed it in one shaped berry that has a strip of cream running across.

Georgia - Is one of you secretly Willy Wonka?

Gabriel - Yeah, pretty much. We wanted to watch it again because if I remembered this quote from Willy Wonka saying that he's showing off his factory and he says the blueberries taste like blueberries and the snozzberries taste like snozzberry. And this is the first time that you can actually make a snozzberry.

Georgia - Have you made a snozzberry?

Gabriel - We've made some weird ones. I don't think we've made a snozzberry, yet. We've made some rum and coconut berries, and all sorts of other interesting things.

Georgia - They sound delicious. So, can we get making one?

Gabriel - Yeah. We've put some fruit juice into this machine and now we're going to select what shape to turn into. We've got some simple preprogrammed shapes. I'm going to choose the little raspberry shape here.

Georgia - This sort of looks a little bit like an ink-jet printer but it's over this small cup of water and it's dropping these little drops of red into it which seem to be sinking and forming a shape very much like a raspberry starting to appear. How long does each fruit take?

Gabriel - It depends on the size. These little raspberries take something like five to ten minutes. We're being quite careful and slow here, so the fastest we've been able to print these fruits is about a minute.

Georgia - So, if you think to yourself, I know a flavour that's going to be really great. Banana and rhubarb maybe and you say to yourself I want to try that, so you can just put the juice in one end, build this fruit with both flavours and then eat it. Is that all there is to it?

Gabriel - Yeah. Pretty much. There's a little bit of magic that goes into it, of course. What's great is you can use pretty much anything you like, these organic fruit juices or things that aren't juice at all like honey, cream, and yogurt, and so forth.

Georgia - And does it need to be in water?

Gabriel - This cup of water that the droplets fall into is a temporary printing medium. So, the printing has to take place in there for this gel membrane to form around each droplet but at the end of the printing process, we fish the berry out of the solution and it stands up by itself.

Georgia - Okay. So, we're just fishing out the finished product. It looks like a sort of very gooey, half melted raspberry at the moment.

Gabriel - What's nice is that you can tune the consistency of these things. So, you can make the resulting object quite flimsy and almost like a jelly so as soon as you pop it in your mouth it kind of dissolves or you can make the droplets fairly strong so that they have a more crunchy texture.

Georgia - Again, I'm going to try my first ever 3D printed raspberry. Hmmm... that reminds me a bit of school jelly actually.

Gabriel - In this case we're using some artificial flavourings so I think that's why for a lot of people, it's reminiscent of things like gummy bears and jellies because they use the same flavourings.

Vaiva - We've been looking to work with chefs around Cambridge to help us develop a bit more interesting flavours but they can be incredibly flavoursome. We can really pack it with interesting flavours.

Georgia - I was going to ask about applications for this.

Vaiva - We were thinking potentially children because it makes it really appealing and looks really kind of nice. And we noticed that children really like to try them. We're also thinking potentially older people. Kind of having problems with drink. Athletes potentially because we can really make it super nutritious and it's very convenient. We're hoping that students potentially will like it because they could have a healthy lifestyle with the convenience of not having to go to supermarket everytwo days and buy fresh fruit.

Georgia - This reminds me of the chapter in Charlie and the Chocolate Factory where there's this sweet, I think it might be chewing gum where they taste it, it tastes like a three-course meal. Can you get berries to taste of things they have layers in.

Gabriel - You're not limited to using sweet things so you can use a layer of fruit juice and then a layer of potato puree or soup or whatever you like. So, that's where the chefs really come into it because there's all this freedom.

Georgia - Does this go beyond the kitchen ever?

Vaiva - Yes. We're looking to apply it in also medicine and maybe even cosmetics. We've been looking to potentially personalize cosmetics and make it more interesting in terms of how it's delivered and how people actually mixing it and how are people applying it. In medicine, it has application for printing tissue. So, yeah. It has wide application beyond kitchen.

50:03 - How is self cleaning glass made?

How is self cleaning glass made?

There are two types of self cleaning glass. The more common one makes use of titanium dioxide nanoparticles that are deposited on the surface. They are not simple pieces of glass, as they are covered in an ultra-thin coating, a layer roughly 10-25 nanometers thick. To put that into perspective, that's about 1000 times thinner than a piece of human hair. The organic dirt that settles on these surfaces is broken down by UV light with the help of these particles. In this way the sun effectively burns away the dirt, but since UV light is required, this works best outdoors and is therefore not ideal for smartphones.

The second effect uses an applied substance that strongly repels water. The resulting surface is super-hydrophobic - water-hating - so repels nearly any substance that it comes into contact with. Any type of dirt is easily removed, by simply rinsing the surface with water, for example in a rain shower. Strictly speaking, this surface is not self-cleaning since it requires water and should therefore rather be termed "easy clean surface". This is still in development and might well be a solution to prevent fingerprints on smartphones in the future, particularly because some of these surfaces also repel oils, so that fingerprints are less likely form readily on these surfaces.

Comments

Add a comment