Naked Engineering - Synchrotrons

Interview with

Ben - Keeping on the theme of particle accelerators, for this week's Naked Engineering, Meera and Dave have been out to the Diamond synchrotron, that's an electron accelerator, based out in Didcot, Oxfordshire where head of engineering Jim Kay gave them a tour of the facility to see just how electrons can be made to move close to the speed of light using a combination of vacuums, magnets and a few other pieces of engineering...

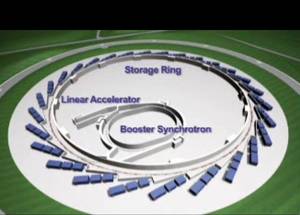

Jim - The Diamond synchrotron is a large scale science facility comprising three electron accelerators which are used in series to produce electrons which are stored in  our storage ring at 3,000 million electron volts (MeV) and at that energy, when the electrons are bent in their orbit they produce high energy x-rays. We extract the x-rays in tangential beam lines to the storage ring and conveyor them down to end stations where the scientists have positioned their sample to expose the sample to x-rays, and take data on how the x-rays interact with their samples.

our storage ring at 3,000 million electron volts (MeV) and at that energy, when the electrons are bent in their orbit they produce high energy x-rays. We extract the x-rays in tangential beam lines to the storage ring and conveyor them down to end stations where the scientists have positioned their sample to expose the sample to x-rays, and take data on how the x-rays interact with their samples.

Meera - The storage ring itself is very large. It has a circumference of 560 metres and the electrons are moving very close to the speed of light. So, how firstly do you even get electrons moving that quickly?

Jim - The electrons start the journey in a cathode and in the cathode, we boil electrons off a heated surface in a vacuum, and then attract them towards a positive plate, the anode, which is held at 90,000 volts. We then inject them into a device we call LINAC, a linear accelerator where now, the energy is added to, but by using RF waves. These RF waves are radio frequency waves and this is a different method of giving energy to the electrons, and in the LINAC, we accelerate the electrons now from 100 KeV to 100 MeV - 100 million electron volts.

Dave - So, this is essentially producing waves of electric fields in a chamber, so little bunches of electrons will surf a wave down the chamber and accelerate down the chamber.

Meera - Well we're now within the synchrotron itself, so we're just towards the end of the LINAC, the linear accelerator, towards the booster section of the synchrotron.

Jim - So we're stood in the booster tunnel which you can see is a large concrete vault and in fact here, the walls and roof are 2 meters thick to absorb the harmful radiation that's produced when electrons are circulating and to keep the dose of the outside of the walls no higher than background.

---

Meera - We've now moved away from the booster into the main storage ring which is  where the electrons move to after the booster section of the synchrotron. We're now next to an insertion device which is actually where the electrons are made into actual x-rays. Jim...

where the electrons move to after the booster section of the synchrotron. We're now next to an insertion device which is actually where the electrons are made into actual x-rays. Jim...

Jim - Basically, the way we produce high energy x-rays is that we expose the electrons to an alternating magnetic field and we produce this by having many permanent magnets which we bring close to the electron beam, and arrange them so that the electrons see an alternating north-south, north-south, north-south field. And as the electrons go through this alternating magnetic field, they wiggle or move side to side and every time a relativistic electron wiggles, it gives off a squirt of x-rays.

Dave - This is a bit like when electrons wiggle up and down an aerial and they give off radio waves, but this is happening far faster, so now, it's x-rays.

Meera - Well this insertion device, it's a very large structure. It's about 3 meters tall, 2 meters or so wide. It's very solid looking...

Jim - This device carries these magnets which we bring very close to the electron beam. The closer we can bring them to the electrons, the stronger the magnetic field, the bigger the kick we can give the electrons. So that's good to produce the high energy x-rays.

Dave - You're talking about the magnets having to be incredibly accurately positioned. Why is accuracy so vital?

Jim - So what we're trying to do is produce a spot of electrons, a focused spot of electrons, 10 microns diameter, so that's a quarter of the diameter of a human hair. At that dimension, so many things can upset the stability of that electron beam. So in terms of stability, we know that at the beam height which is 1.4 metres above the floor, if the temperature in here which are changed by 1 degree C, that beam height would change by more than 20 microns which is more than twice the diameter of the electron  spot size. So we know that to keep the temperature very stable in here is key and hence, you can see all this heating and ventilating duct work providing air at 22 degrees C. You can also see that the electromagnets, these very big red and yellow magnets, which have water cool coils because of the current density that we need to drive these magnets, and the water cooling is also provided at 22 degrees C. And hence, by the air being at 22, the water at 22, we minimise the heat transfer and hence, the contraction and expansion of all these metallic components.

spot size. So we know that to keep the temperature very stable in here is key and hence, you can see all this heating and ventilating duct work providing air at 22 degrees C. You can also see that the electromagnets, these very big red and yellow magnets, which have water cool coils because of the current density that we need to drive these magnets, and the water cooling is also provided at 22 degrees C. And hence, by the air being at 22, the water at 22, we minimise the heat transfer and hence, the contraction and expansion of all these metallic components.

Meera - So stability is clearly a key engineering challenge with regard to Diamond and the minimisation of any movement. At regular intervals along around the storage ring, there are surveying points - maybe every 10 metres - which are, I imagine, just making sure that nothing is moving?

Jim - As you can imagine as we look down the tunnel here, we can see it very quickly curve out of view. But we're trying to align each of these girders carrying these magnets to within 0.1 mm of its neighbour and around the whole of 560 meters circumference, we're trying to align everything within a global cylinder of confusion of 1 mm diameter. In order to do that, we've got a very accurate survey network using some very precise theodolites and a process of automatic target recognition when we carry out a survey, to position these magnets with such high precision.

Meera - Well another factor to consider for the stability is the ground that the synchrotron is on...

Jim - Yes, very true and we've built a very strong floor that carries the accelerator and all the beam lines that are linked to the accelerator. We want to guarantee that the x-rays produced at the focal point of the electrons have the best chance of getting to the sample point, maybe 40 meters or more away, and not lose any definition or be blurred by vibration or by differential settlements. So the floor we've built is 800 mm thick under our feet here and carried, in the whole facility, on over 1500 piles which are 600 mm diameter and penetrating down to 15 meters into the chalk. It's extremely stable and we've used a system called a hydrostatic levelling system where over a 60-meter length, we've been measuring the level of the floor, accurate to a few microns over the last year, and we know now that over 10 meters, our stability has achieved our 10 microns per 10 meters per day stability requirement.

- Previous Supersymmetry and the LHC

- Next How do you throw spears?

Comments

Add a comment