A mirror that cannot get dirty, and a meshwork capable of instantly separating oil from water have been developed by scientists in the US.

Both technologies are based on a special surface treatment based loosely on the famed self-cleaning physics of a lotus leaf.

Both technologies are based on a special surface treatment based loosely on the famed self-cleaning physics of a lotus leaf.

Writing in Nature Scientific Reports, Ohio State University researchers Philip Brown and Bharat Bhushan came up with the new coating by applying a thin layer of a sticky polymer called PDDA (polydiallyldimethylammonium chloride) onto a glass slide.

Silica (sand) nano particles were then sprinkled into the polymer to produce a bumpy contour resembling the surface of a lotus leaf. This was capped off with a further layer of PDDA into which was mixed molecules of a fluorine-based surfactant molecule that attracts water but repels oils.

Water dripped onto the surface spreads out into a uniform thin film that doesn't distort light passing through. Oily substances, on the other hand, forms tiny droplets that readily roll off the surface.

The optical properties are reasonable, meaning that the coating could be used as a treatment to prevent mirrors becoming filthy, which would be useful in roadside settings.

More impressively, the coating could be used to produce a sieve device that could rapidly separate oil from water.

Brown and Bhushan sprayed their silica nanoparticles onto a fine steel mesh and topped them off with their surfactant-laced PDDA mixture.

The result was a sheet that could be held at an angle over a bowl. A mixture of oil and water poured onto the meshwork filled the bowl with water while the oil ran off sideways into a separate receptacle.

It works because the surfactant molecules on the surface break down the surface tension or stickiness of the water, allowing tiny droplets to pass through the mesh. The oil, however, is repelled by the surfactant layer and remains as large globules too big to pass through.

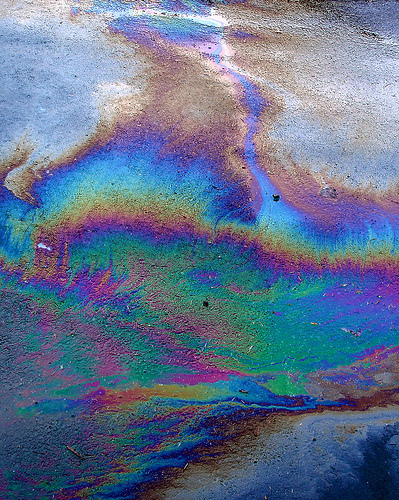

The coating is cheap and easy to make at scale, meaning that it could be used for environmental cleanup operations for instance, dealing with oil slicks.

It also has the advantage over other forms of oil filter that it doesn't become clogged with use, because the oil just runs off while the water passes straight through.

- Previous Drugs Kick-Start MS Repair

- Next What makes knuckles crack?

Comments

Add a comment