Scientists have used 3D printing techniques to construct a new temporary windpipe and successfully treat a child born with an airway obstruction.

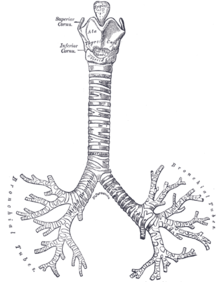

Twenty month old Kaiba Gionfriddo has tracheobronchomalacia, a  condition which affects the trachea, the long tube which connects our larynx (or voicebox) and our lungs.

condition which affects the trachea, the long tube which connects our larynx (or voicebox) and our lungs.

The role of this strong cartilaginous tube is to keep the airway clear, but patients with tracheobronchomalacia suffer from flaccid cartilage, meaning that the airway can collapse and obstruct breathing.

This condition affects 1 in every 2,200 children, and while most grow out of it, 10% of cases are serious and some children, like Kaiba, regularly require resuscitation.

But Glen Green and his colleagues at the University of Michigan were able to treat Kaiba by using a 3D printer to produce a plastic tracheal splint, a small hollow tube which could keep his airway open.

Rather than construct a permanent repair, the team instead used polycaprolactone, a bio-compatible and bio-degradeable polyester which, placed inside a person, slowly breaks down over a number of years.

This treatment was carried out in February 2012 and Kaiba was able to be taken off a ventilator 21 days after treatment. He has had no difficulty with breathing since this time. The tracheal splint should biodegrade within about 3 years, the same amount of time that it will take for his trachea to grow into a healthy state. This means the small tube will not be around to obstruct his airway when he's older.

The team hope that the 3D printing process can be used to produce other tissue structures in the future and have already begun building ear, nose and bone structures in pre-clinical models.

- Previous Why can't penguins fly?

- Next Quickfire Science: Oklahoma Tornado

Comments

Add a comment